Categories

- C4I, Communication Systems

- Electrical, Electronics & Electro-optics

- Other Aerospace, Defence and High Technology related companies

Variass, as a system supplier and Electronic Manufacturing Services (EMS) specialist of client-specific electronic and mechatronic products and systems, focuses on the defense, medical, water and industrial markets. The company's focus is on small and medium size series with a high variety (high mix, low volume, high complexity).

Variass' customers are usually global market leaders in their sectors. This obviously results in intensive cooperation in the chain. The knowledge and experience within the Variass Group can be utilized in the various but similar markets. If applicable, the Group can take care of the worldwide distribution on behalf of customers in order to keep the lines short and the integral costs low.

Turnover share per market:

• Defense 24%

• Medical 31%

• Water 8%

• Industry 37%

Variass Group

The Variass Group is a private enterprise consisting of various complementing companies, each with its own specialization and responsibilities. Together they form the major links in the chain of the system supplier. As chain managers we cooperate intensively within the Variass Group and various partners to achieve a complete service package. The ultimate result is that this collaboration delivers more than the sum of its parts.

Horizontal competencies within the group:

• Project Management

• Life Cycle Management

• Supply Chain Management

• Material Management

• Quality Management

• After Sales

Operating competencies:

• Development and engineering

• Production and assembly

• Testing

• Service & repairs

• Warehouse management

System Supplier

As system supplier, Variass consolidates the most important services and takes over specific responsibilities from the OEM manufacturer. The company's cooperation with the customer contributes greatly to:

• Industrial design (via the customer and partners)

• Project management

• Process management

• Development & Engineering

• Logistics & Purchase (SCM)

• Production & Assembly

• Testing

• Value engineering

• Life Cycle Management

• After-sales

In addition, Variass can take care of customers' distribution in order to keep the lines short and the integral costs low.

Project management

Variass uses measuring systems, transparent consultation structures, a high level of knowledge, and independent teams of flexible and engaged employees to safeguard project management.

Depending on the demands, a variable multidisciplinary project team is put together, consisting – for example – of the account manager, project engineer and operation manager. Their input is knowledge and understanding from a variety of perspectives. Within the project NPI (New Product Introduction) and time-to-market are achieved as efficiently as possible.

Process management

Variass produces approximately 600 different semi-finished and end products that are produced from about 11,000 active parts. The company's strong points are high mix, low volume and high complexity. This entails enormous variety and demands involvement and critical thinking from Variass' staff. Lean thinking and working and the correct documentation (digital or otherwise) in the workshop ensure the process and enable the production employees to work effectively and efficiently.

High reliability of delivery

Variass can guarantee at least 95% reliability of delivery by using an appropriate workload control by means of POLCA and mySAP All-in-One. This methodology and software enable the organization and the customers to work just-in-time. This reflects in an optimum response to the needs of the customer.

Production report

After delivery of the first production series, the company drafts a production report in which indicates how the process has run its course, including any possible improvements. The document provides both parties with points of attention for improvements and/or adjustments; this is for the benefit the customer and Variass.

Development & Engineering

Thinking in terms of solutions

For the customer, Variass is a full-scale discussion partner with sound knowledge about project-based, product technological and process technological professional fields.

Variass can assist, guide and advise customers right from the very start. The intention is a perfect end-result for them and ultimately, their own clients. Variass aims to make complete products and systems by which it can utilize its logistical concept as best as possible, but that depends on the customer’s wishes: intermediate schemes are also possible. Variass makes a difference by looking for and finding customer-driven solutions.

Development & Engineering

Variass is the suitable partner for supporting customer in:

• Designing, developing and engineering Printed Circuit Board Assemblies (PCBA), casings and systems

• Printed Circuit Board (PCB) layouts

• Re-design

• Value engineering

• Design for Excellence (DFx): Manufacturability, Testability and Cost effectiveness

• NPI (New Product Introduction)

• Certification counseling

Short lines between development and production

Variass can guide customers in introducing their product. Following the design, the company starts to manufacture a prototype and after that, a 0-series. Variass can be a major asset in the process of value engineering, which is finding the balance between the various indicators such as functionality, quality and costs. Variass has a ‘protoshop’ (= prototype workshop) in which the Product Development (PD) department builds, tests, evaluates and works on product improvement and the possibility to manufacture the product.

Logistics & Purchase

Perfect logistics of the entire track is an essential requirement for meeting reliability of delivery; Variass' standard in this is more than 95%. All parts should be present at the right location at the correct time for the proper cost price. That requires knowledge, commitment, organizational capacity, flexibility and the right systems.

To guarantee the quality and delivery times of the parts that should be purchased, Variass purchase department has concluded strategic cooperation relationships with appropriate suppliers. All possible actions are taken to ensure that the production of customers' products does not suffer delays.

Production & Assembly

Reliable production chain

Having its own tooling shop allows the company to make the most of its client-specific tools. Furthermore, it facilitates a fast switch to production. Variass' skilled employees guarantee the chain’s quality and end result. Extensive testing during the entire process ensures that clients will receive perfectly functioning products only.

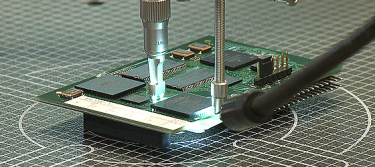

Print Circuit Board Assembly (PCBA)

A core competence of Variass is assembling industrial PCBAs. For Surface Mount Technology (SMT), Variass uses ultra-modern JUKI machines. These machines are capable of placing components with 01005 casings into 150x50mm components with a pitch of 0.25 Quad Flat Package (QFP) and 0.25 mm Ball Grid Array (BGA). Forced convection ovens are available for the reflow-soldering process. In addition, the company also has a Through Hole Technology (THT) assembly line. Variass' production is suitable for the lead-free process as well as the lead-containing process (if exempt). In addition, the company employs a certified IPC trainer who regularly trains employees.

Product protection

If necessary, the PCBAs can undergo a special treatment to protect them from a variety environmental and/or weather influences. There are different techniques for protecting the products, such as:

• Casting

• Casing (pot process)

• Coating

Box building & Systems

A separate Variass department is responsible for box building and assembling systems. This department combines the assembled PCBs with other electronic/mechanical parts into semi-finished or complete end products. To implement this accurate procedure even more, Variass works with a 6S systematics, which means a fixed arrangement of the workshop that result in increasing the productivity and the precision.

Testing

Variass is able to deliver products that are fully tested by subjecting the PCBAs and the products to one test or a combination of tests that are mentioned below:

• Inspection using an Automated Optical Inspection (AOI) machine and Ersascope

• Boundary scan

• In Circuit Component Test

• Functional test

• Stress test

• X-ray

• Climate test

• Safety tests and high-tension tests

Value engineering

Value engineering is an important process in the life cycle of a product with the intention of improving the price-quality ratio. The costs of a product are determined to a large extent during the design phase. Cost reductions can usually be achieved by cooperation and knowledge exchange. Its experience puts the company in a position to contribute to this.

Life Cycle Management (LCM) of the product

A fast changing market forces us to respond to the unpredictability of material provisioning. During the lifespan of a product – from product development to phasing out – Variass relieves customers of all worries related to the production process of a product.

Thanks to its extensive network and knowledge of the total chain, its many years of experience and modern tools, the company is capable of managing the entire life cycle of customers' product. Variass focus is always on the end result because the functioning of customers' product should never become an issue.

After-sales

Customers' relationship with Variass does not come to an end when a project is completed or an order has been delivered. The company's after-sales are well thought-out and are safeguarded by its employees. This procedure fits in Variass' aim to build a long-lasting and valuable relationship with customers and optimal client value.

Service & repair

Variass has its own Service & Repair department. Complications can occur in the life cycle of the product due to handling by the end-user or because of environmental conditions. Variass can serve customers or their clients by executing the necessary services and repairs of the products.

Warranty & Service

Variass automatically offers a one-year warranty on delivered products, but customers can turn to Variass for professional service even after the warranty period. If the product does not entirely function as can be expected, Variass can use various tests to detect the cause of the fault and provide customers with the support they need.

Defense

Variass is an assembly company (PCBA and box building), which focuses specifically on the defense market. This concerns high-mix, low-volume and high-complexity products that are assembled in accordance with Class 3 of the Institute for Printed Circuits (IPC). Variass is an AQAP 2120 and ISO 9001 certified organization.

CV90

The CV90 together with the Fennek reconnaissance vehicle and the Boxer armored vehicle takes over the tasks of the current YPR vehicles that were up for replacement. BAE Systems Hägglunds (BSH) of Sweden developed and produced the CV90. The vehicle is equipped with modern, digital information systems and an electronic control and operating system, which Saab Aerotech of Sweden developed. In 2005, a contract for supplying technologically high-quality communication and navigation systems was concluded with Saab Aerotech. As of 2006, these systems are delivered for peace-keeping missions to the Netherlands (192 items), Denmark, Norway, Finland and Switzerland.

Variass has taken care of the electronics and box building for the CV90. Based on high client satisfaction, a long-lasting relationship has been built, and now new projects have been outsourced to Variass.

Boxer project

The Boxer project is a joint venture project of the German and Dutch defense establishments for building a new armored vehicle. The order consists of electronics and box building for the Command & Control systems of 472 ultra-modern armored vehicles. The Boxer is a wheeled armored vehicle for transport and medical use and it is an international project of the German (Krauss-Mafei Wegmann and Rheinmetall Landsysteme) and Dutch (Rheinmetall Nederland) industries.

Variass Systems is proud that the order was placed shortly after Variass became the first partner in the Netherlands to receive the coveted A status from Rheinmetall Landsysteme. Thinking along in the industrialization process and the guarantee of the feasibility to make the products generates extra client value.

Medical

Variass has a great deal of knowledge in the area of medical applications and products, guidelines and technical norms. The company's focus is on non-invasive medical and analysis products. Variass is an ISO 13485 and ISO 9001 certified organization.

Pathco

Pathco is a paraffin-coating machine used in laboratories and hospitals to prepare a piece of tissue removed from a patient, before it is examined under the microscope. Pathco is unique mainly because the system does not use the harmful chemical Xylene and has a much shorter processing time. Pathco works with CO2 that spreads more evenly and penetrates the tissue better.

Variass Medical Systems has made the design, the entire hardware & software and mechanical composition of the Pathco for Tispa Medical. The company cooperated intensively with Feyecon engineering office that was responsible for the chemical process.

Due to project management and intensive cooperation with the customer, engineering, logistics, purchase and production, Variass Electronics has performed optimally. Ultimately, the end client has not experienced any inconvenience from the switch in delivery.

Kidney Assist

Organ Assist originally comes from the University Medical Center Groningen (UMCG). The purpose of Organ Assist is selling reliable systems that preserve organs for a longer period of time and thereby increasing the success rate of transplants.

Variass Medical Systems has developed the Kidney Assist (among other things) and it is produced in series. This system enables isolated hypothermic oxygen-rich blood flow of the donor kidney during transport from the donor to the recipient in a transplant procedure. This portable system stores the kidneys in a hypothermic manner in which the oxygen is beneficial for supporting the low yet active metabolism. In addition, the company assisted Organ Assist in drafting the technical file for CE marking.

Simulix

Nucletron is global market leader in the brachytherapy, a method to treat tumors by radiating them from the inside. The Simulix is a radio-therapeutic simulator. The simulator locates the tumor by means of an X-ray camera. It also determines under which angle(s) and with which surface the radiation bundle can best be brought to the tumor. Ultimately, all settings determined with the simulator are transmitted to the radiation device.

Since the nineties, Variass Medical Systems produces and assembles various parts and modules for the Simulix, including the collimator, the entire operating panel and the control. A collimator brings about a parallel X-radiation and is a perfect example of an assembled, complex mechatronic product.

Water

Variass has a lot of knowledge in the area of applications and products, directives / guidelines and technical norms. Variass is an ISO 9001, ISO 13485 and AQAP 2120 certified organization.

Watter module

The company's customer has developed a system with which a disinfectant can be produced on site. The system has enormous application possibilities e.g., hospitals can use it to disinfect water. Most disinfectants are harmful for human beings and the environment. By contrast, the Watter system produces a disinfectant on site that is not only biodegradable and pH neutral, but is at least just as effective as the currently used agents.

The core of the Watter system is based on the principle of anodic oxidation or electro-diaphragmalysis and it was originally developed in the space program of the Soviet Union. Anodic oxidation is an effective technique for making a powerful disinfectant from two simple ingredients (water and salt), which is biodegradable and is just as effective as currently used agents such as bleach.

Variass has industrialized the product into a product that can be reproduced and it takes care of the series production and assembly plus its distribution.

Q-watch

Capilix focuses on the market of modular sensor solutions based on lab-on-glass-chip technology and it has special knowledge in the area of microchip capillary electrophoresis.

Capilix develops these platform technologies in online analysis instruments for use in various industrial environments that are predominately water-related.

Variass Medical Systems together with the customer has developed the Q-watch based on the functional specifications. Capilix provided the input for the analytical part of the machine and Variass developed and industrialized these into a product.

Industry

As system supplier and EMS specialist, Variass is active for customers in a variety of market sectors with semi-finished up to complete end products.

Variass is active in the following market sectors:

• Agro-industry

• Domotics

• Energy

• Measuring & control technology

• Telecommunication

PCBA development

Kwant Controls has been developing and producing nautical operating instrumentation since 1937. Propulsion installations sometimes become overloaded without being noticed. For this purpose, a haptonomic module was developed that makes such a load sensible. The module serves as a direct interface between man and machine. The current generation of levers and joysticks, which control rudders and propulsion motors of ships, move so easily and evenly that a navigation officer does not feel what the effect of his action is on the propulsion installation or the rudder.

Variass Engineering made the layout of these PCBAs and developed them based on the functional specifications. During the development, industrialization was taken into account. As a result, the time to market was considerably shortened. Variass Engineering takes care of producing the PCBAs.

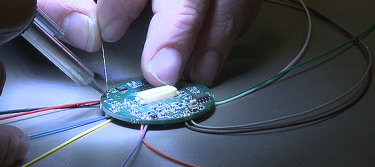

Flex and flex-rigid

Flex PCBs and flex-rigid PCBs are applied more and more in cases where the design determines whether moving parts are going to be used. This requires special knowledge about the application and the correct choice of a PCB manufacturer. Since 2001, Variass Electronics has gained valuable experience in assembling these high-tech PCBs. In the meantime, more than 300,000 items in different variations have been assembled for the defense and industrial markets.

PCBA

For more than 25 years, Variass has also assembled PCBAs (SMT and THT) in small and medium size series with a high variety (high mix, low volume, high complexity) for the defense establishment, medical, water and industrial markets according to IPC Class 2 & 3: from prototype building to series of 5,000 items.

Lexguard blind spot detection system

Variass has developed Lexguard for Intertruck. This blind spot detection system is unique as opposed to other systems, in providing an active warning system. The active blind spot detection system operates by means of a plastic strip attached to either the right side of the trailer, the bicycle-guard or directly to the body front and right side. This strip “feels and sees” if anyone is in the blind spot during a right turn and gives a visual and audible warning signal to the driver in the cabin.

The detection system assists the driver by drawing attention to vulnerable road users where other systems do not. The biggest added value of this system is in reducing the number of dead and injured road users.

Additionally, this system helps to reduce the total amount of material damage caused. It is certainly true that this system reduces the risk of extra costs such as damage claims, absenteeism due to sickness and inability to work etc.

Variass was actively involved during this whole project. Directly after Intertruck approached us with their idea for Lexguard, Variass made an inventory of all the possibilities. Variass was responsible for the complete route from prototype to finished product, including embedding Lexguard’s sensors.

Navigation and communication systems

Variass has produced navigation and communication systems for the Ministry of Defence commissioned by Saab. The equipment has been manufactured in accordance with quality norm AQAP and IPC-A-610 class 3.

Fire protection systems

Variass has produced a completely automatic, stand-alone fire extinguishing system for Nofiq. Thanks to an ideal combination of carbon monoxide and temperature detection, the system can detect, extinguish and communicate an incipient fire at an early stage. The detection equipment is connected via hubs to a base station, where all alarm signals are registered. The field of application is switch boxes, meter cupboards and computers.

Hearing glasses

The idea for the hearing glasses came from Varibel themselves. Although the concept was technically worked out, the product needed to be made producible and sellable on the consumer market.

The project was a big challenge for Variass due to the large number of points of special interest. Variass focussed on the producibility of the printed circuit board in the legs of the spectacles and the development of the battery holder and charger.

The legs of the hearing glasses contain four miniscule microphones which amplify the sound coming from the front and reduce that coming from other directions. This enables the user to listen without strain in a noisy environment, and hear better from the direction in which the user is looking. The glasses are a special salvation to the elderly.

This was a special project, considering that Variass produces mainly industrial electronics. The hearing glasses are a top product for Variass in terms of miniaturisation.

Variass B.V.

- Cereslaan 4 9641 MJ, Veendam, The Netherlands

- +31 598 61 94 75

- contact@variass.nl

- www.variass.nl