Categories

- Composites, Plastics & Rubber

- Metal Processing, Parts & Components

Kanfit, is an engineering and production company ( Built to Spec ) that offers high level of expertise in design and innovative manufacturing solutions, manufacturing technologies, assembly techniques and the capability to tailor the right production methods to customer's standards, requirements and budget. Kanfit is a turn key subcontractor with the abilities to manufacture and deliver complete work packages. Kanfit, is a privately owned company established in 1986, and is one of the most experienced manufacturers in the Israeli aerospace market.

The company possesses various manufacturing technologies and is focusing on:

* Composite parts and bonded assemblies including advanced RTM & LRI technology.

* Metallic airframe primary parts & assemblies.

* Plastic hot forming and transparencies.

* Tooling for production and assembly of airframe parts, metallic and composites.

Kanfit is AS 9100B and NADCAP certified and a certified supplier of aerospace products for key players in the Israeli aviation market such as IAI - Israel Aerospace Industries, Israel Air force, Ministry of Defense, Elbit Systems group, Rafael, and more. As a major subcontractor to IAI, parts and subassemblies manufactured by Kanfit, are assembled and delivered to final customers such as Gulfstream, Boeing, Lockheed-Martin, and many more.

Kanfit is among the market leaders in the Israeli composite market, with outstanding abilities to develop and deliver complete prototypes from 3D model ( Built to Spec ). Challenging products are a passion for us. We turn our customers' most complicated concepts and ideas, to serial -production products. Our extensive manufacturing experience, knowledge about the materials we use and our innovative thinking, aids our customers throughout the entire process of design, prototypes building, tooling and mass production, to design and achieve better products.

Kanfit has been a subcontractor to aerospace, aerospace related and medical devices companies since 1986. Kanfit main service is subcontracting based on 3D models ( Built to Spec ) supplied by the customer, using a large variety of production technologies. To enable high service level, most of the needed production technologies for our current abilities are in house technologies. New technologies are constantly being examined to improve our work, performance and quality, and to supply our customers a complete solution.

Parts and assemblies manufactured by Kanfit are supplied directly to the assembly line of our customers, with no need for further inspection. Kanfit manufactures primary parts, kits and assemblies. Kanfit manufactures kits for assembly lines since 1992, assemblies since 1996, and medium scale assemblies since 1997. Kanfit also has a crew for installations and modifications of aircrafts at the customer site.

Kanfit has been awarded the following certifications and accreditations:

- AS9100C & BS EN ISO9001:2008

- Nadcap for Chemical Processing

- Nadcap for Heat Treatment (conductivity, hardness, mechanical testing)

- Nadcap for Composites (AC7118 Rev D-Audit criteria for Composites, including AC7122-P-Audit Criteria for Non Metallic Part Manufacturers Captive Laboratories). Click here to learn more.

- Boeing cerfitication: QMS; Heat Treatment of aluminum alloys; Temperature inspection of non-ferrous alloys; Coating

- Israel Aircraft Industries Commercial Aircraft Group certified supplier

- BAE Systems (Rokar International) certified manufacturer

- Israel Air Force certified manufacturer

- Israel Ministry of Defense certified supplier

- Elbit Systems Group certified manufacturer

- Cyclone aviation products certified manufacturer

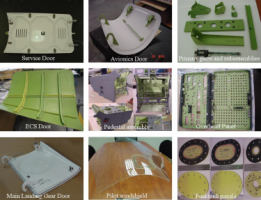

Aircraft components

Business Jets:

Gulfstream G250, G150, G200 (Galaxy), G100 (Astra)

Kanfit is among the largest subcontractors for Israel Aerospace Industries, commercial aircraft group. Parts manufactured by Kanfit include primary parts, sub-assemblies and assemblies such as Pedestal assembly, Overhead Panel assembly, Main landing gear door, Avionics door, ECS door, service door, and more.

Commercial aircrafts:

Boeing 787, 777, 747, 767, 737, MD-11, Dornier D28

Primary parts, sub assemblies, tools, master gauges, transparencies, etc.

Military aircrafts:

F15, F16, F4, Skyhawk

Wing pylon check gauges, Central pylon drilling fixtures, access panels, fuel tank parts, primary parts, fabrication tools, doors, etc.

UAV components

Israel Aerospace industries (IAI) - Eitan, Heron, Hunter, searcher

Elbit systems - Hermes

Manufacturing of airframe components, prototypes, tools, fixtures, bulkheads for the wings and body, fuel system parts, and more made of composite and metallic materials such as Heron engine cowling, Searcher engine cover, Primary parts, assemblies, Kits to shop (below), Composite fuselage (Mould 3.5 meters long), etc.

Kanfit is the major aircraft structure component supplier for IAI - Israel Aerospace Industries MALAT division (UAV development and manufacturing division).

Helicopter components

AH64-apache, UH60-Blackhawk, CH53, Bell 212, AH1-Cobra, Mi17, Mi24, Mi35,

Manufacturing of composite and metallic parts, upgrade kits, windows assemblies (CH53 mini-gun window assembly), composite instrument panel glare shield, composite covers,, windows prototypes, tools, moulds for composite parts, fixtures, primary parts, subassemblies, installations and modifications.

Aerospace accessories

Extremely high precision tooling for manufacturing and assembly of space mounted GRE antenna. Composite robotic arm with vacuum and camera canals for silicon wafers handling. The arm thickness is 2mm. UAV flight controls calibration set. Composite materials mini UAV operator control box. High precision Avionics rack. Glass epoxy Laser calibration system cover, hermetically sealed.

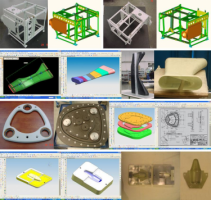

Production engineering

The engineering department in Kanfit, has extensive experience with transforming the most complicated concepts to serial production products. Using the latest CAD/CAM/CAE software versions of CATIA and UNIGRAPHICS, our engineers turn concepts in early development stages into prototypes, tools, serial production models, working instructions, methods, process specifications and serial production.

Our Digital Process Definition specification is certified by IAI - Israel Aerospace Industries, which in turn, is certified by Boeing, Lockheed-Martin, Gulfstream, etc.

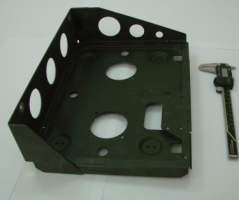

Metals

Kanfit manufactures primary airframe parts, sub assemblies and assemblies. Manufacturing starts from raw material such as sheet metal, Block and extrusion, from various types of alloys, through machining, forming, heat treatment, chemical coatings, finishing and assembly if needed.

Among our Facilities are:

• CNC machining centers

• Milling machines

• Lathes

• Chemical conversion line

• Aerospace painting chamber

• Brake-Press

• Presses, up to 500 ton

• Argon TIG welding

• Guillotine

• Heat treatment ovens

• Hardness and conductivity testing tools

• -40ºC freezers

Kanfit is certified by it's customers to supply primary parts and assemblies directly to production line, reducing the expensive need for incoming inspection and warehousing costs. All parts are supplied with COC and are manufactured according to customers quality requirements and the AS/EN9100B certified quality assurance system procedures.

Composite materials

Composites

Over 20 years of accumulated experience has made Kanfit into one of the leading companies in the Israeli composite structures manufacturing market. During that period, Kanfit had built a vast knowledge base that enables it to deal with the most sophisticated production tasks and challenges, and produce state of the art composite structures. Our knowledge and experience make an important contribution for our customers while developing new prototypes, products or improving and modifying existing products.

Using Composite materials encompass an unrivaled composition of strength, weight, cost and availability that can not be found in any other solution. The usage of composite materials enables a unique freedom of surface design, variable thickness and surface texture. Our expertise allows us to achieve extremely tight tolerances in composite structures.

Kanfit specializes in Resin Transfer Molding, Liquid Resin Infusion and wet lay up manufacturing techniques. All technologies enable us to embed metallic inserts in the composite structure with very high quality of adhesion between the components.

Our clean room facility is environmentally controlled (temperature, humidity, positive pressure).

Resin Transfer Molding (RTM)

RTM manufacturing technology - a dry fiber is placed in a closed mold, resin is then injected under some combination of pressure and vacuum, followed by curing cycle. This technology enables Kanfit to manufacture composite parts in high volumes with less labor and lower costs, while keeping quality to the aerospace and medical industry standards. Parts manufactured using RTM technology are reproducible with very tight tolerances. .

Liquid Resin Injection (LRI)

LRI manufacturing technology - a dry fiber is placed in an opened mold, than covered with a vacuum bag. The resin is then injected under some combination of sub atmospheric pressure and vacuum.

Wet Lay Up

Wet Lay Up manufacturing technology is among the earliest technologies for composite structures manufacturing, but allows unequaled structure forming flexibility. Dry fiber is placed on the mold or master and than saturated manually with resin. Each piece of fabric is placed in that way until the desired part is formed. The complete part is than sent to be cured, using vacuum bag to extract excessive air and resin. This stage also help to the compaction of the layers.

Bonded assemblies and embedded metallic components

Kanfit has a unique expertise and more than 20 years of experience in this field. We specialize in very difficult and complex composite assemblies with metallic, rubber, plastic, honeycomb, foamed and even electrical components.

Plastics

As part of our one stop shop concept, Kanfit also manufactures parts from various kind of plastics (Kydex), rubbers (cork rubber, neoprene etc), transparencies (Perspex), Rohacel, and various other non-metallic materials. Among the various manufacturing technologies used for these parts are hot forming, vacuum forming, machining of thick glass epoxy / fenolic plates and more.

Tooling

Among our expertise is design and production of tooling for airborne structure assemblies, molds for composite manufacturing, RTM & LRI molds, bending, press working, jigs & fixtures for welding forming assembling drilling and more. Combining our tooling skills, experience and prototyping capabilities, enables Kanfit to provide its customers a full set of proven tools, ready for serial production.

We use every available manufacturing technology to ensure that production tools are of the highest possible quality. Tools are made of various metals, composite materials, rubber, plastics and various combinations of materials.

Kanfit

- Hatzoran street, Southern Ind. Park, 23100, Migdal Haemek , Israel

- +972-4-616-9300

- +972-4-616-9380

- www.kanfit.com