Categories

- Aircraft, Helicopter, UAV, Spacecraft & related equipment

- Maintenance Repair Overhaul and Logistics Support

- Mechanical, Electro-mechanical, Hydraulic and Pneumatic components

- Metal Processing, Parts & Components

Aeronamic successfully develops, manufactures, tests and maintains complete high-speed rotating systems for the aerospace industry. Aeronamic is a Dutch high-tech company with state-of-the-art capabilities that employs over 160 staff at their facilities in Almelo, The Netherlands and Síbiu, Romania. The Company combines the most cost-effective manufacturing processes with full commitment to customer satisfaction.

Aeronamic's expert staff are active in the development and application of new technologies to play an important role in future programs by introducing new technological solutions at (sub)system level to reduce weight, manufacturing cost and operational cost. The company manufactures subsystems with highly accurate rotating parts for nearly three decades as this originally tied in well with the nature of the ultra-centrifuge manufacturing of Urenco, its former parent company.

Maintenance, Repair & Overhaul

Aeronamic’s Maintenance, Repair & Overhaul is a true center of excellence approved under EASA part 145. The Company's MRO operations benefit from the in-depth system design knowledge at Aeronamic. Specialized engineering teams systematically improve system reliability and drive down operational cost by implementing state-of-the-art repairs in the Component Maintenance Manuals and Service Bulletins.

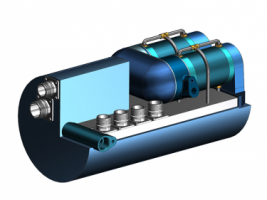

A330 GTCP 331-350 LOAD COMPRESSOR

This Load Compressor for the Airbus A330/340 and Airbus A330 NEO series provides high pressure air for cabin pressurization and air conditioning. It also powers the Air Turbine Starters for the main engines.

Aeronamic is the single source supplier and responsible for the design, testing, series production, spare parts and field support of the Load Compressors. Since 1996 over 1200 new compressor units have been delivered. All compressors in the field are being kept in excellent condition by Aeronamic’s Maintenance, Repair and Overhaul facility.

KC46A GTCP331-400 LOAD COMPRESSOR

This Load Compressor for the Boeing B767-400 series provides high pressure air for cabin pressurization and air conditioning. It also powers the Air Turbine Starters for the main engines.

Aeronamic is the single source supplier and responsible for the design, testing, series production, spare parts and field support of the Load Compressors. The new program for the KC-46 Pegasus new-generation aerial refueling tanker aircraft fleet for the US Air force will demand around 200 compressors. All compressors in the field are being kept in excellent condition by Aeronamic’s Maintenance, Repair and Overhaul facility.

A350 VAPOR CYCLE SCROLL COMPRESSOR

Aeronamic is the single source supplier for the Scroll Compressor system used for cooling the galleys and avionics for all versions of Airbus A350. Tests and full assembly of the Scroll Compressor system is performed in The Netherlands whilst parts manufacturing is undertaken in our facility in Sibíu, Romania. Aeronamic is also in charge of the system’s Maintenance, Repair and Overhaul for the lifetime of the aircraft program.

OEM Subsystems

F35 PTMS FORWARD MODULE

Aeronamic is awarded a life-of-program contract to produce the F35 Forward Module, as part of it’s Power and Thermal Management System.

The Forward Module is a very power dense system that integrates a number of flight critical functionalities such as: Starter engine for the APU; Electrical power generator; Cooling turbine; Emergency power generator

A330 GTCP 331-350 LOAD COMPRESSOR

This Load Compressor for the Airbus A330/340 and Airbus A330 NEO series provides high pressure air for cabin pressurization and air conditioning. It also powers the Air Turbine Starters for the main engines.

Aeronamic is the single source supplier and responsible for the design, testing, series production, spare parts and field support of the Load Compressors. Since 1996 over 1200 new compressor units have been delivered. All compressors in the field are being kept in excellent condition by Aeronamic’s Maintenance, Repair and Overhaul facility.

KC46A GTCP331-400 LOAD COMPRESSOR

This Load Compressor for the Boeing B767-400 series provides high pressure air for cabin pressurization and air conditioning. It also powers the Air Turbine Starters for the main engines.

Aeronamic is the single source supplier and responsible for the design, testing, series production, spare parts and field support of the Load Compressors. The new program for the KC-46 Pegasus new-generation aerial refueling tanker aircraft fleet for the US Air force will demand around 200 compressors. All compressors in the field are being kept in excellent condition by Aeronamic’s Maintenance, Repair and Overhaul facility.

A350 VAPOR CYCLE SCROLL COMPRESSOR

Aeronamic is the single source supplier for the Scroll Compressor system used for cooling the galleys and avionics for all versions of Airbus A350. Tests and full assembly of the Scroll Compressor system is performed in The Netherlands whilst parts manufacturing is undertaken in our facility in Sibíu, Romania.

Aeronamic is also in charge of the system’s Maintenance, Repair and Overhaul for the lifetime of the aircraft program.

C17 AIR COOLING MACHINE

Aeronamic produces the Air Cooling Machines for Boeing C17 aircraft, forming part of the complete Environmental Control System.

Aeronamic also supplies the spare parts for the C17 fleet and for various Environmental Control Systems used in veteran aircraft platforms such as the DC10, MD11, Airbus A300/310 and Fokker JetLine series.

ROLLS ROYCE TAY AIR TURBINE STARTER

Aeronamic manufactures, assembles and tests the Air Turbine Starter for the Rolls-Royce Tay turbofan.

Aeronamic’s Air Turbine Starter is designed to meet the speed, power, safety and reliability needs of turbine engine starting systems powering regional airliners and business jets worldwide, such as the Fokker JetLine series, Gulfstream G350 and G450 jets.

Aeronamic also manufactures the Rolls Royce BR710 Air Turbine Starter.

ROLLS ROYCE TAY STARTER VALVE

Aeronamic manufactures, assembles and tests all the Air Starter Valves for the Rolls-Royce Tay turbofan.

Designed to meet the speed, power, safety and reliability needs of turbine engine starting systems they power regional airliners and business jets worldwide such as the Fokker JetLine series, Gulfstream G350 and G450 jets.

ROLLS ROYCE BR710 AIR TURBINE STARTER

Aeronamic manufactures, assembles and tests the Air Turbine Starter for all Rolls-Royce BR 710 engines.

Aeronamic’s Air Turbine Starter is designed to meet the speed, power, safety and reliability needs of turbine engine starting systems powering regional airliners and business jets worldwide such as the Gulfstream G500 and G550 jets and the Bombardier Global 5000 and 6000 series.

ROLLS ROYCE BR710 STARTER VALVE

Aeronamic manufactures, assembles and tests all the Air Starter Valves for the Rolls-Royce BR710 engine.

Designed to meet the speed, power, safety and reliability needs of turbine engine starting systems they power regional airliners and business jets worldwide such as the Gulfstream G500 and G550 jets and the Bombardier Global 5000 and 6000 series.

Parts Manufacturing

AIR SEPARATION MODULE CANISTER

Aeronamic’s Air Separation Module Canisters are an essential part of the onboard fuel tank inerting safety system widely used on large platforms ranging from Airbus A320, A330, A340, A350, and A400M series to regional Sukhoi and Bombardier aircraft.

Multi-axis machines with superior 7-axis capability enable us to hold extreme tight tolerances and to further reduce machining production time and cut cost to a minimum.

MACHINED CASTINGS AND HOG-OUTS

Complex precision components can be manufactured either from raw materials or castings in a very short time combining milling and turning whilst significantly improving quality.

A switch from machined casting to hog-out (C2HO) for complex aerospace components reduces cost, weight, supply chain risk and cycle time – a huge advantage in our business.

TURBINE WHEELS, ROTORS AND IMPELLERS

Annually Aeronamic produces thousands of turbine wheels, fans, impellers and high-speed turbine rotors for various applications on a wide range of aircraft systems.

Manufactured with state-of-the-art production machines these critical and complex aerospace components demonstrate high reliability at low cost.

Product Development

Aeronamic is EASA Part 21 certified. The Company is capable of designing systems to specification up to qualification and industrialization. This includes working according to the recognized ARP and DO standards for software and hardware development.

ELECTRIC STARTER GENERATOR (SGU)

Starter and generator function are combined in this system and optimized for safety and long time between overhauls (>5000hrs). Rated starter performance is 20kW/30Nm and the machine weighs approximately 7 kg. A unique safety feature is to withstand internal and external shorts without overheating. A mechanical disconnect system, which allows the machine to be put to a stand still in case of bearing failure is optional. Compared to Air Turbine Starters and DC Electrical Starters, Inverter Driven Starters can be controlled more accurately. This allows actively suppressing torsion oscillations producing smoother torque profiles.

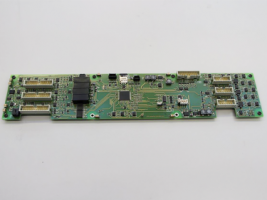

DIGITAL ELECTRONIC CONTROL UNIT (ECU)

The digital ECU for the Electric Starter Generator integrates a control board, an inverter board and a unidirectional HVDC-LVDC converter board in one housing. The ECU is designed for starting on a bus voltage of 270VDC, but can be reconfigured to work with an 115VAC/400Hz bus.

The ECU includes a novel fault detection algorithm which instantaneously detects potential faults in the machine. Its rated performance is in starting mode 20kW/270VDC and in generator mode 12kW/28VDC. The ECU weighs approximately 14 kg.

DIGITAL MOTOR CONTROLLER (DMC)

The Aeronamic Digital Motor Controller for PM machines uses a novel sensorless control algorithm that allows full control of the machine torque even at very low speeds. The inverters are based on a robust thermal design that allows the starting power to be up to 3x higher than the rated generation power. The control software can be configured to include fault detection, which allows appropriate actions to render the PM machine safe in case of internal failure.

DC/DC CONVERTER

Aeronamic HVDC/LVDC converters deliver a regulated 28V at 300A to supply user loads. They feature resonant topology to deliver high efficiencies by means of soft-switching. Highly integrated magnetics result in low weight while meeting insulation requirements. The converters offer full protection including over current of 150% rated current.

ELECTRICALLY DRIVEN COMPRESSOR (EDC)

Aeronamic is currently developing a High-speed Electric Centrifugal Compressor for cabin pressurization, vapor cycle, fuel tank inerting and fuel cell systems. These systems are supplied with inverter, sensorless control and run on foil bearings lubricated with process gas.

TURBO COMPRESSOR (TC)

Aeronamic has developed a High-speed Turbine Driven Compressor for pressure boosting of the bleed air. Air foil bearings and an optional variable inlet guide vane system provide optimum variability of the working point within the compressor map. Emphasis is placed on low cost and high reliability, resulting in a modern scaleable unit without castings. Rated compressor power is 28kW and it weighs approximately 10kg.

Customers

Aeronamic customer base include:

- Boeing

- Gulfstream

- Rolls-Royce

- Bombardier

- Airbus

- Fokker Aerospace

- Honeywell

- Enrichment Technology

Aeronamic B.V.

- Planthofsweg 79 7601 PJ, Almelo, The Netherlands

- +31 546 545 570

- info@aeronamic.com

- www.aeronamic.com