Categories

- Mechanical, Electro-mechanical, Hydraulic and Pneumatic components

- Military, Tactical, Logistic Support Vehicles & related equipment

- Services (R&D, training, engineering, consultancy, …)

CONTROL POINT E.U., is an external resource for companies that require design, manufacturing and dimensional control services for their products. Through the implementation of technology and specialized software, as well as very competitive delivery times, CONTROL POINT E.U. ensures a high level of satisfaction for its customers by delivering high quality solutions, allowing profitability and sustainability in the market and driving industrial growth with the support of an experienced group of professionals.

VISION

CONTROL POINT E.U. ambitions to remain at the technological forefront with regard to CAD / CAM processes. The Company aims to be a leader in the design and product engineering by improving its technological processes and achieving recognition at a national and international level.

QUALITY POLICY

CONTROL POINT E.U. is focused on maintaining and improving customer satisfaction through the design and manufacture of the best quality products, the strengthening and implementation of the principles of organization-oriented training, research and the continuous improvement of processes with the support of providers acting at a national and regional level.

Contact info #1

Machining & Manufacturing Services

Machining in 3-5 axis (static), based on applications developed within the Company; CONTROL POINT E.U. has the capability to perform milling of any shape about at least 2 axes.

Additionally, the Company is able to manufacture complex prototypes made of epoxy resin or polyester reinforced with fibreglass.

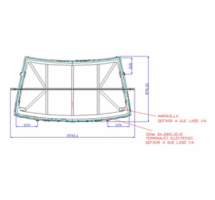

2D Modeling

Using printed or digital drawings, as well as CAD files, CONTROL POINT E.U. can adjust the dimensions of the client’s products and generate virtual models. Through a graphical representation in 2D, unknown aspects on the product can be displayed as it is possible to calculate distances and create various possible 2D models.

3D Modeling & Prototyping

From physical samples or 2D drawings, a 3D virtual model of a product can be obtained. 3D models provide a detailed digital approach of the product’s characteristics allowing for different shading, textures, shapes, translucency and depth, among others.

Through the 3D modeling of a product, as well as virtual and audiovisual presentation, virtual prototypes can be obtained.

CNC Prototyping & Product Development

Through physical prototyping, it is possible to inspect and evaluate the shape, style and ergonomics of a product and compliance with the related specifications and standards before going into full production. Prototypes and models can be made of synthetic material, such as Nylon, Empac, MDF, Fiberglass, polyurethane, acrylic, aluminum, or stereo lithography.

Additionally, CONTROL POINT E.U. offers CNC product development services and the main products developed through this process are:

• Injection Moulds,

• Blow Moulds,

• Thermoforming Moulds,

• Hot Pressing Molds,

• PU Molds (Foams).

HEFIMEC LTDA.

Cutting Tool Services.

IAC COLOMBIA LTDA.

Engineering Software.

Control Point E.U.

- Carrera 32 No. 10 86, Cundinamarca, Bogota, Colombia

- +57.3125880460

- control.point@outlook.com

- www.control-point-design.com