Categories

- Electrical, Electronics & Electro-optics

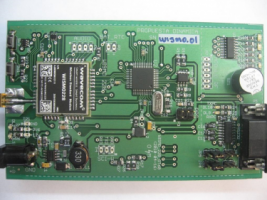

PRODUCTRONIKA, is a company located in the city of Medellin, Colombia and founded in 2007 by a group of professionals with several years of experience in electronic assembly activities. The Company specializes in assembly services related to single and double sided printed circuit boards for both Insertion Mount (IMT) and Surface Mount (SMT) technologies.

MISSION

PRODUCTRONIKA’s mission is to satisfy customers’ needs through the assembly of single and double sided printed circuit boards, thus enabling them to introduce new electronic components in the design of their products and at the same time support the development of the regional electronic industry.

VISION

PRODUCTRONIKA’s vision is to become the best platform for regional development and the manufacture of printed circuit boards. The Company gives great importance to its customers and the cooperation with third parties in order to offer a specialized portfolio of services.

Contact info #1

Electronic Boards

The Company manufactures electronic boards in two main ways:

Prototyping: boards that are usually assembled in very small quantities (up to 10 units of the same type), a service that is primarily carried out by students, electronics designers and the design department of manufacturing companies. The evaluation of the prototypes is measured in hours; delivery times are between 1 and 3 days from the moment when the components, materials and specifications become available.

Production: this is a service offered to companies that require a regular provision of electronic boards. Delivery times and prices are defined following an initial quotation. During this phase, the customer must provide a sample and specifications, so that PRODUCTRONIKA can correctly evaluate the price and delivery times. Additionally, the organization has an agreement with the company PROPUESTA DINÁMICA, for the provision of components, as well as assembly services.

To carry out these services, PRODUCTRONIKA takes into account the following:

-

Type of service (prototype, production),

-

Number of boards per delivery,

-

Dimensions of the boards,

-

Type of welding (leaded or unleaded),

-

Single and double sided printed circuit boards,

-

Components involved in the assembly.

PRODUCTRONIKA's technologies, especially the type of assembly and the welding processes, are as described below:

Assembly: the electronic components can be welded though THT – Through Hole Technology, which refers to the use of leads on the components that are inserted into holes drilled in printed circuit boards (PCB) and soldered to pads on the opposite side either by manual assembly or by the use of automated insertion mount machines. The welding process requires specific tools, techniques and logistics.

Welding: welding is the most important part in the assembly process, as it defines the electrical and mechanical characteristics of the device (component-printed circuit board). In terms of composition, traditional welding uses tin-lead alloys. In some countries the welding process contains no lead alloys and in these cases it is used a tin-silver alloy that melts at a higher temperature and has a slightly duller finish.

Production Flexibility

The capability to produce in low and medium volumes gives the Company the flexibility to serve two different industry sectors: design and research applications for the industrial sector.

Productronika

- Calle 80A # 41-35 - Medellin, Medellin, Colombia

- +57 4 444 9005

- productronika@gmail.com

- www.productronika.com