Categories

- Mechanical, Electro-mechanical, Hydraulic and Pneumatic components

- Metal Processing, Parts & Components

Borsodi Muhely Ltd. is a renowned Hungarian manufacturer of metallic components for the automotive and electrical equipment industries. The company operates and keeps developing an integrated Quality and Environment Management System in compliance with the standards of EN ISO 14001:2004 and EN ISO 9001:2000. The company's measuring laboratory is certified in line with ISO 17025 standard.

Production

Over the last 28 years Borsodi Muhely has developed a very high professional experience in the production of unique components. The technologies applied use the best possible tooling machines operated by highly qualified workers in order to fulfil customers’ quality expectations.

Measurement

Borsodi Muhely Ltd. main focus is on quality. The quality control of the parts produced is performed in a well-equipped measurement room by well-qualified professionals. The controlling gauges Borsodi Muhely produces are calibrated in the company’s meter laboratory that is certified by NAT which has been operating since 2005. Moreover, Borsodi Muhely undertakes the control and accredited calibration of parts, gauges and manual meters produced by other companies.

Heat Operations

One of the main elements of the 1 billion-forint development of Borsodi Muhely Ltd. was building the heat operating plant. The installation of the plant started in the spring of 2008 and it was taken over on July 11th. In the company’s 250 sq. m. plant there are the most modern heat operating machines, which guarantee the highest level of quality of work performed. Borsodi Muhely also performes heat operations for third parties.

Contact info #1

Accredited Measurement Laboratory

ACCREDITED LABORATORY (According to ISO 17025)

MEASURING PRISMS (0,5…100mm)

- steel measuring prism

- hard metal measuring prism

GAUGES

- barrel (0,1…120mm)

- external (2…92mm)

- ring (1…92mm)

- screwed barrel (M2…M110)

- screwed ring (M2,5…M42)

- custom-built

TRADITIONAL METERS

- vernier caliper (0…300mm)

- depth vernier caliper (0…300mm)

- altitude meter (0…300mm)

- micrometer (0,5…100mm)

- dial indicator (0…60mm)

- angle gauge (0…360°)

3D Milling

Milling tooling is done by 5 HURCO-type computer-controlled tooling centres. One of the machines is able to do 5-cylinder milling, with which free surfaces can be created.

The main characteristics of the machine are:

- tooling size: 500 x 710 x 500

- tooling accuracy: + - 0,05 – 0,02 mm

5D Milling

In 2007 Borsodi Muhely installed a HERMLE C30U-types 5-cylinder CNC tooling centre that is appropriate not only for tooling complicated surfaces but also for the so-called hard machining and speed machining (40,000 recs / min).

The main characteristics of the machine are:

- Tooling size: 630 (table size: 540 x 540)

- Tooling accuracy: + - 0,05 mm

Lathe Tooling

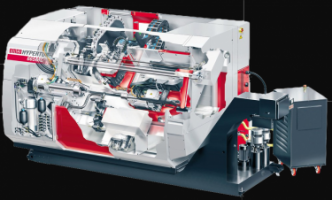

As well as traditional tooling machines, CNC-controlled tooling machines and the high-technology EMCO HYPERTURN 645 MCplus 8-cylinder tooling centre also produce parts. The 8-cylinder tooling processes are extremely favourable from the viewpoint of productivity. With the help of the turning lathe centre, milling (surfaces, pockets, islands and nuts), drilling, thread tooling, tread milling, thread drilling, profile milling and gearing can be performed.

The main characteristics of the machine are:

- Tooling size: Ø400x740

- Tooling accuracy: ±0,01 mm

Drilling

Except for the traditional, highly precise drilling machines, following the development of the technology, the company bought a Fehlmann Piccmax 54 CNC Coordinate drilling machine, with which the performance and accuracy of drilling can be enhanced.

The main characteristics of the machine are:

- Tooling size: 500 x 260 (table size: 800 x 320)

- Tooling accuracy: + - 0,02 mm

Spark Tooling

Borsodi Muhely owns one Sodick CNC block spark tooling machine and two Sodick CNC wired spark tooling machine. Moving all the three shafts of the block spark tooling machine by linear drive is the latest known technology that makes the production of complicated, high quality geomatrical items possible.

The main characteristics of the machine are:

- Tooling size: 270 x 300 x 200

- Tooling accuracy: + - 0,005 mm

The linear, motor-driven movement of the company's CNC wired spark tooling machine and its most modern control make it possible to produce greatly precize goods with special geometrical instructions.

The main characteristics of the machine are:

- Tooling size: (230 x 320 x 200)

- Tooling accuracy: + - 0,005 mm

Rubbing

Rubbing technology at Borsodi Muhely means flat, skirt, bore, profile and coordinate rubbing. Among the company's traditional, precise rubbing machines, the Studer S33-type CNC universal skirt rubbing machine, which can satisfy the highest customer needs in the field of tooling. Borsodi Muhely’s high-technology appliance is the most modern rubbing technology in the world.

The main characteristics of the machine are:

- Tooling size: tooling items of diameter of 250 mm and length of 700 mm

- Tooling accuracy: + - 0,002 mm

Other equipment included in Borsodi Muhely's machine park include HAUSER coordinate rubbing machine with which +-0,005 bore position can be ensured; TOYO bore rubbing machine, with rubbing capability of maximum 300-400 mm long bores with a diameter of 40 with 0,005 mm bore accuracy, which is unique in Hungary; Wasino Winstar CNC flat and profile rubbing machine that is suitable for even more cylinder rubbing at the same time and for precise tooling of special shapes.

Etchwork

Borsodi Muhely applies FineMarker-100 laser engraver, which is appropriate for marking tools, medical instruments, and freebies. UID and data-matrix (2D) can be engraved, as well as barcodes (1D), illustrations, logos, names and notices with any letter type on pens or key rings, or photos on plated medals in excellent quality.

Customers

- ZF

- BORGWARNER TURBO SYSTEMS

- GRABOPLAST RT

- AUDI

- BP

- GM

- EPCOS

- CONTINENTAL

- KNORR-BREMSE

- RG

- LUK

- ALCOA

- TDK

- BOSCH

- DANA

Borsodi Muhely Ltd.

- Juharfa u. 8. H 9027, Gyor, Hungary

- +36 96 529 071

- info@borsodimuhely.hu

- www.borsodimuhely.hu