Categories

- Composites, Plastics & Rubber

- Electrical, Electronics & Electro-optics

- Other Aerospace, Defence and High Technology related companies

- Services (R&D, training, engineering, consultancy, …)

ELECTROPORCELANA GAMMA S.A., was founded in 1962 and is part of the Corona Group, a multinational group of companies founded at the end of the 19th century, which to date employs more than 9,700 people worldwide.

ELECTROPORCELANA GAMMA S.A. manufactures and commercializes electrical insulators, protection equipment and fittings, among others to utility companies, OEM's and electrical distributors.

The Company started exporting its products to the American continent over 40 years ago. The Company's main markets include countries, such as Colombia, United States, Venezuela and Mexico, as well as the South American region, Europe and Asia.

Its quality products, state-of-the-art infrastructure, human and financial resources and good understanding of the market has positioned the Company among the leaders in the manufacture of electrical equipment.

In 2001, the Company began commercializing its products to Lapp Insulators under their own brand in the United States and Canada. In September 2009, ELECTROPORCELANA GAMMA S.A. bought from Lapp Insulators the distribution business associated to its products for the North American market.

Contact info #1

Metrology Services

ELECTROPORCELANA GAMMA S.A., offers metrology services from the identification of critical variables to calibration services, such as equipment inspection, measuring and traceability testing according to national and international standards, ensuring quality and reliability in the final product.

Porcelain Insulators for Distribution & Transmission

Suspensions

ANSI Class 52-1 to 52-6, 52-9 10.000 pounds (44 kN), 15.000 pounds (70 kN), 18.000 pounds (80 kN), 20.000 pounds (90 kN) and 25.000 pounds (111 kN) fog type insulators until 18.000 pounds (80 kN).

Spools

ANSI 53-1 to 53-5.

Guy Strains

ANSI 54-1 to 54-4.

Pins

Simple and radio pins ANSI 55-1 to 55-5, 55-7 and 56-1 to 56-3 (with & without RF).

Line Posts

ANSI 57-1 to 57-3, 57-5.

Station Posts

TR-202, TR-205, TR-208, TR-210,

TR-214, TR-216.

Raw Materials Analysis & Slip Formulation

Raw materials are categorized in terms of chemical composition, mineralogy, and physical and ceramic properties. These properties are used to create the optimum blend for high quality ceramics.

Ball Clay Beneficiation & Slip Batching

These processes use low and high intensity dispersers, hydrocyclones, sieves, and magnetic traps. Batching is carefully performed according to the weight and volume of the item.

Filter Pressing

Process in which high pressure is used to remove water from the conveyor belt to obtain flat plates with a consistent material density. Work pressure up to 200 PSI.

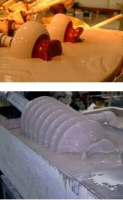

De-airing & Extrusion Equipment

Flat plates are de-aired in a vacuum pug mill. Final products are extruded with optimum compaction and homogeneity. Pug mill hole diameter up to 13”.

Wet & Dry Turning

Horizontal and vertical hydraulic lathes are available for shaping cylindrical pieces up to 1.2 meters long. Lathes are automatically controlled for the optimal sequencing of operations. Tungsten carbide tools with high wear resistance are used.

Pressing Process

A heated die is pushed while turning the extruded item inside a gypsum mold. Optional threading is available.

Drying & Firing Kiln

Gas fired dryers and kilns are suitable for water removal and ware sintering. Shuttle and tunnel kilns are available for temperatures up to 1300°C. Dryers support temperatures of up to 140°C.

CLIENTS

Among ELECTROPORCELANA GAMMA S.A.’s most prominent clients are:

- ISA,

- CODENSA,

- EPM,

- ENDESA,

- UNION FENOSA,

- AES,

- AEI,

- CFE,

- ECOPETROL,

- OXY - OCIDENTAL PETROLEUM CORPORATION,

- PETROBRAS,

- DRUMMOND COMPANY INC.

Electroporcelana Gamma S.A.

- Carrera 49, No. 67 South 680, Sabaneta, Antioquia, Colombia

- +57 4 305 80 01

- tvallejo@corona.com.co

- http://www.gamma.com.co/