Categories

- Aircraft, Helicopter, UAV, Spacecraft & related equipment

- Maintenance Repair Overhaul and Logistics Support

- Services (R&D, training, engineering, consultancy, …)

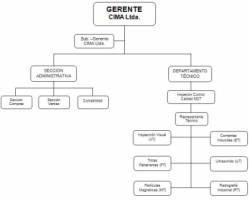

CIMA LTDA. - COMPANIA INTERNACIONAL DE MANTENIMIENTO LTDA., is a company dedicated to providing maintenance services to the Aerospace and Industrial sectors. The Company seeks to forge a competitive advantage over its rivals, by providing high quality maintenance, engineering calibration, Non-destructive Testing services on aircraft and aircraft equipment, among others, improving fundamental aspects, such as quality, delivery times and prices in order to create greater added value in every negotiating process.

Contact info #1

AIRCRAFT MAINTENANCE

CIMA LTDA. - COMPANIA INTERNACIONAL DE MANTENIMIENTO LTDA. offers aircraft maintenance services with qualified, trained and licensed personnel:

-

Execution of major inspections, scheduled and unscheduled maintenance,

-

Fuselage and major structural repairs,

-

Painting services (paint removal and application),

-

Remodeling of aircraft interior,

-

Weight and balance services.

Non-Destructive TESTING SERVICES

Equipment & Accessories

- Establishment of calibration references for ultrasound and eddy currents,

- Supply of inspection equipment,

- Supplies and accessories for quality control in all techniques,

- Inspection equipment repair.

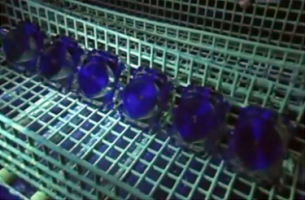

Dye Penetrant: Application of dye penetrant from the inspection of critical parts, such as aircraft components to ceramic tableware.

Advantages

The dye penetrant inspection is extremely sensitive to surface discontinuities. The configuration of the parts to be inspected is relatively easy. Dye penetrant inspection is reasonably fast in terms of application and the equipment can be portable.

Magnetic Particles: Magnetic particle inspection is used in different branches of the industry, such as the metallurgy, aviation, shipbuilding, construction sectors, etc. and applies to:

- Raw material inspection,

- In-process inspection,

- Finished product inspection,

- Maintenance of equipment and machinery,

- Inspection is used to weld cast, forged, rolled materials, etc.

Advantages

The inspection process is relatively quick, of low cost and adaptable to portable equipment. In addition, liquid penetrant requires less cleaning and can detect subsurface discontinuities. In addition, better results are obtained in detecting discontinuities filled with contaminants, such as coal, slag, etc. that cannot be detected in a penetrant inspection.

Phased Array Ultrasound

The Company's ultrasound phased array method allows for fast inspection with precise cross-sectional images and detailed internal structures. The phased array technology uses multiple elements and electronic time delays to create scanned, focused or targeted beams that allow for a quick inspection, a complete data storage and inspections from different angles. This technology provides precise measurements with highly reliable results. In the US, this technique is replacing industrial radiography as it is safer for the operator and the environment as well, offering a high degree of reliability through 3D imaging.

Remote Visual Inspection

Remote Visual Inspection is suitable for the measurement of damage depth, for recording video and taking pictures.

Application: Inspection of boilers and heat exchangers, turbines, engines, gearboxes, etc.

Eddy Currents

-

Inspection of pipe heat exchangers and boilers.

-

Inspection of aircraft structures.

What is the Eddy current testing (Eddy or Foucault Currents)?

A magnetic field creates electrical disturbances known as Eddy currents that are capable of changing shape. The shape change can be translated into electrical signals that can be recorded. Eddy current tests help detect surface irregularities, such as cracks and pits before they cause forced outages and downtime.

Magnetic material tubes (used in boilers) can be inspected with the use of saturation or the RFT technique (Remote Field Testing) using an amplifier.

Eddy Current Procedure On Boilers and Heat Exchangers: Using Eddy currents, it is possible to examine tubes for the detection of general and local erosion or corrosion. The technique can detect defects in the pipe wall and in the area beneath the supporting structure/fittings. Even bimetallic tubes can be inspected for defects on the outer and inner tube or defects in the junction zone between the two materials. It is also possible to detect unwanted material stuck to the outer wall of the tube.

Eddy current testing is normally conducted by two qualified inspectors and data are stored on the hard drive of a PC for further analysis and reporting. Results are presented in a map with different colours indicating the defects on the material.

X-Ray Inspection Technology

X-Ray Inspection Technology is suitable for locating corrosion, loss of thickness and hidden cracks.

Structural flaws: holes, elongation, rivet loss, structural integrity analysis.

Steel thickness of up to 30 mm.

Infrared Thermography

Thermography is a technique that detects radiation in the infrared range of the electromagnetic spectrum and produces images of that radiation, called thermograms. Thermograms allow for a qualitative and quantitative analysis of the obtained image, and inspectors are able to calculate the temperature on any part of the image. The primary objective of this technique is to provide support related to the inspection of components in a system, allowing failure anticipation.

-

Electrical systems: cables, boards, circuit components;

-

Control components, such as valves, etc.

-

Pipes.

* In the case of inspection, the temperature is used as an indicator of an abnormal condition. Abnormalities on safety valves, carbon deposits and steam traps can be observed using thermography in furnaces, boilers, reactors, chimneys, gas pipelines, tanks and isolated ducts, among others.

Dynamic Balancing

Adjustments to the balance of the structure/assembly are performed using the Company’s proprietary test benches and equipment. The lack of balance in a structure/assembly is one of the common causes of vibration/flutter in rotating machinery. The ability to distinguish vibration attributable to the lack of balance in a given structure from other possible causes of vibration is an essential first step in the related analysis.

There are several methods that help determine if the cause of the vibration is lack of balance:

-

Vibration Spectrum Analysis,

-

Waveform,

-

Phase 1X.

Types of balance according to ISO 1925:

-

Static Balance,

-

Quasi-static Balance,

-

Dynamic Balance.

ISO 1940/1 or VDI 2060 Certification: This certification applies only to rigid rotors. A rotor is considered rigid when at its maximum operating speed it rotates at a speed not greater than the first critical speed. In practice, a rotor is considered rigid when its speed is less than 0.5 or less than 0.7 times its first critical speed.

Laser Beam Alignment

The life span of bearings, seals and couplings is closely linked to the degree of alignment. Alignment is one of the maintenance practices that should be performed under strict control and with accuracy.

Advantages of laser beam alignment against mechanical alignment:

-

Curl bars,

-

Hysteresis,

-

Low resolution, 1/100 mm,

-

Measurement errors,

-

Mechanical Behaviour,

-

Inclined Indicator,

-

Axial Behaviour.

ENGINEERING SERVICES

CIMA LTDA. provides professional services on structures and electrical systems for the modification and repair of military and civilian aircraft.

-

Preparation of engineering documents for the modification of aircraft and aircraft parts manufactured under international standards.

-

Structural strength studies through finite element analysis.

-

Fatigue and damage tolerance analysis on military and civil aircraft.

-

Design and implementation of non-destructive inspections.

-

Design and implementation life extension programs for aircraft.

-

Consultation on workshops and certification capabilities to the relevant aviation authority.

-

Design and manufacture of jigs and special tools for third-level maintenance.

CALIBRATION SERVICES

Through an agreement with a foreign calibration laboratory, CIMA LTDA. has the ability to calibrate NDT equipment, tracking equipment, oscilloscopes, luggage balance and weight, vibration analysers, battery chargers, aeronautical measurement tools, test benches, in accordance with the ISO 17025, ANS/NCSL2-540-1 FORMER, MIL-STD-45662A, MIL-STD 271F, ISO 9000 and MIL-STD-271F standards.

Aeronautical Supplies

CIMA LTDA. is a distributor of Air Data Test Sets of the renowned Italian company D. MARCHIORI S.R.L. (DMA) - DMA-AERO, as well as a variety of aeronautical supplies, such as:

-

Composites,

-

Chemical adhesives and sealants,

-

Aircraft paints,

-

Tools,

-

Hardware,

-

Air Data Test Sets,

-

Cleaning products.

Cima Ltda. - Compania Internacional de Mantenimiento Ltda.

- Carrera 96J #23A-55, Bogota, Colombia

- +57 1 486 5851, +57 1 404 0601

- info@cima-co.com

- www.cima-co.com