Categories

- Metal Processing, Parts & Components

- Services (R&D, training, engineering, consultancy, …)

- Ships, Vessels, Submarines & related equipment

TECSUD S.A.S., is a technological company that for more than twelve years has been providing technology solutions to the productive sector related to packaging products, quality control and preventive and predictive maintenance.

TECSUD S.A.S.’s goal is for its products and services to be the first hand tools to its customers, meeting the highest quality standards internationally.

TECSUD S.A.S. has represented several international companies succeeding in staying ahead in technology. The company’s biggest associate is CREAFORM 3D, a technological company that provides portable scanner solutions.

Contact info #1

Contact info #2

Contact info #3

Contact info #4

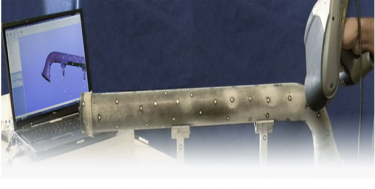

NDT Solutions - Pipecheck – Pipeline Integrity Assessment Software

PipeCheck represents an innovative, intuitive and highly effective solution for both pipeline external corrosion and pipeline mechanical damage assessment and is the best alternative on the market to traditional NDT methods.

PipeCheck for pipeline external corrosion assessment: In order to avoid plumbing failures, inspections are conducted for the assessment of the state of tube degradation and the remaining life time.

External corrosion module: The pipe external corrosion module offers fast, efficient and simplified data processing able to generate results instantly.

The data are presented in Excel, and provide greater accuracy and repeatability than traditional measurement methods, such as ultrasound probing (UT) or line lasers.

Key Features:

-

Automatically-applied interaction rules.

-

3D and 2D color mapping with river-bottom path overlay.

-

2D section generation in both axis.

-

Worst-case-profile generated for all corrosion features.

-

Estimated burst pressure calculation based on ASME B31G code (B31G, B31G Modified and Effective Area methods).

-

Corrosion depth measurement, dimensions and position on the pipe.

-

“Depth-on-the-fly”: simply drag the mouse over point to obtain local corrosion depth measurement.

-

Gouge and redressed gouge inspection.

-

Point-to-point distance measurement directly in the 3D model.

ADVANTAGES

-

Handyscan 3D™ laser scanners can be easily transferred.

-

The scanner is automatically placed in the tube. Encoders or bulky mechanical scanners are not needed.

-

The resulting dynamic link between the pipe and the scanner maintains the accuracy and resolution in any vibratory field.

-

The quality of the data collected can be verified in real time and the results are generated within minutes.

-

The scanner design and the automatically generated reports guarantee the repeatability of the results.

-

The experience of the person performing the inspection has no effect on the process of scanning and analysis.

-

Complies with ASME B31G code regulations.

PipeCheck for pipeline mechanical damage assessment: Functioning pipes should be inspected on site in order to assess the extent of dents or cracks and estimate the remaining life time. In addition to ensuring the integrity of the pipe network, it is necessary to keep costs as low as possible.

Auto Parts Inspection

TECSUD S.A.S. can provide high quality 3D engineering services for the automotive and transportation sector. Its portable 3D measurement technologies can be used in:

-

Style, design and reverse engineering,

-

Prototype development,

-

Simulation and manufacture,

-

Quality control and inspection.

Manufacturing Services

TECSUD S.A.S. can improve manufacturing processes and reduce production costs offering effective services. If necessary, the company’s technicians and engineers can provide their services directly in the plant, assembly or production line.

TECSUD S.A.S.’s manufacturing service offering includes:

-

Quality control and inspection services,

-

Tool and machine design and adjustment services,

-

Work instructions services.

3D inspection using phase controlled EMAT antennas

Inspection is necessary in order to assess the degree of degradation and the remaining lifetime of structures and complex components, such as dovetails, nozzles, feeding tubes, pipelines etc. To facilitate this complicated procedure, the industry typically uses the method of inspection using phase controlled EMAT antennas.

More specifically, the scanner is automatically placed on the part that needs to be inspected. Using triangulation and binocular vision, the Handyscan 3D™ scanner can guarantee high repeatability and measurement accuracy of the 3D data.

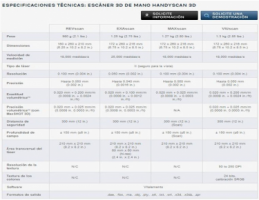

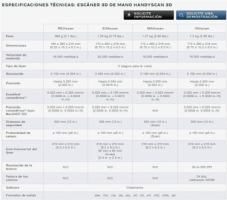

CREAFORM 3D offers two 3D laser scanners to choose from depending on the level of precision required by the inspection.

Handyscan 3D™- Portable 3D Scanner

CREAFORM 3D has developed an extensive line of 3D scanners for portable use, such as the Handyscan 3D™ - Portable 3D Scanner that is available from TECSUD S.A.S.

CREAFORM 3D’s portable scanners are using TRUaccuracy technology, ensuring accuracy regardless of the environment, the object’s configuration and the level of user experience.

Handyscan 3D™ - REVscan™ Laser Scanner

CREAFORM 3D has developed an extensive line of 3D scanners for portable use, such as the Handyscan 3D™ - REVscan™ Laser Scanner that is available from TECSUD S.A.S.

REVscan™ is a reliable tool and an integral and innovative product from the Handyscan 3D™ line of self-positioning scanners. Revolutionizing the production of reverse engineering, design, shape acquisition and 3D inspection methodology, the REVscan™ is a unique, affordable scanner that is highly popular and utilized among many other industries.

Handyscan 3D™ - EXAscan™ Scanner

Handyscan 3D™ EXAscan™ is a viable option for scanning highly detailed surfaces and small objects in many fields such as aerospace, automotive engineering, consumer products and more.

The EXAscan 3D™ laser scanner is equipped with a third high definition camera which greatly increases scanning resolution as well as data acquisition accuracy.

Handyscan 3D™ - MAXscan™ Scanner

The MAXscan™ is the obvious choice for 3D scanning of larger parts. It has the high accuracy of Handyscan 3D™, enhanced with photogrammetric capabilities.

Handyscan 3D™ - VIUscan™ 3D Color Scanner

VIUscan 3D™ color scanner is a self-positioning, handheld laser scanner that delivers hyper-realistic results, thanks to features such as the simultaneous texture and the geometry acquisition, the real-time rendering, the true-color acquisition through a built-in lighting system, the adjustable uniform texture resolution, and the automatic 100-percent-accurate texture mapping.

Quality Consumer Products

As far as product design projects are concerned, TECSUD S.A.S. is synonymous to high quality and efficiency. TECSUD S.A.S. specializes in turnkey projects and project development services (style / design of products). The company has created strong partnerships with reputable companies such as Bombardier Recreational Products, Black & Decker, Kimberly-Clark, Reebok and Kohler.

CREAFORM 3D - Handyscan 3D™ Software and applications

- VXelements™: The Handyscan 3D™ scanners come with VXelements, a fully-integrated 3D data acquisition software that powers its entire fleet of 3D scanning and measurement.

- VX scan software™: VxScan is used exclusively to acquire and optimize 3D digitized data and delivers high performance results.

- VXelements Express™: UNIscan, the basic alignment model of Handyscan 3D™ includes VXelements Express. This simplified version, easier to use than VXelements has been developed in order to match and maximize the functions of UNIscan.

Compatible Software:

- Geomagic (Studio and Qualify),

- Rapidform (XOS, XOR and XOV),

- InnovMetric Software (PolyWorks),

- Dassault (CATIA V5, SolidWorks),

- PTC (Pro / Engineer),

- Siemens (NX and Solid Edge),

- Autodesk (Inventor, Alias, 3ds Max, Maya and Softimage).

- TRUaccuracy: TRUaccuracy Technology: Handyscan 3D™ offers high precision 3D scanning in real operating conditions.

- Automatic positioning: Handyscan 3D™ scanners are data acquisition systems that simultaneously incorporate their own positioning system. This means that there is no need for a tracking or positioning device externally.

- The system uses optical reflectors in order to create a referral "fixed" system to the object in question. The user can move the object as desired during the scan session, so that changes in the environment, such as vibration and stability, in no way affect the quality and accuracy of data acquisition.

- Quick Calibration: The scanner can be calibrated as often as necessary (every day or before a new scan session). Scanner calibration takes about 2 to 3 minutes and ensures optimum performance at all times.

Applications:

-

Reverse Engineering/Design, style and analysis,

-

3D Scanning in CAD format,

-

Style and design modifications,

-

As-built CAD modifications,

-

Class A coating,

-

Vehicle design and style,

-

Spare part design,

-

Digital models,

-

Digitization of clay models,

-

Custom parts design,

-

Design of cutting tools and molds,

-

Mechanical design,

-

Tools and jigs design,

-

Packaging design,

-

Rapid prototyping/3D printing,

-

Finite element analysis – FEA,

-

Maintenance, repair and overhaul.

Heavy Industry & Medical Care Sector Applications

CREAFORM 3D measurement technologies have the biggest advantage in the heavy industry. Thanks to their compact size, light weight and strength, it’s easy to transport them to the working site.

TECSUD S.A.S. has worked on the following projects:

-

Development of parts and accessories for industrial equipment,

-

Repair and maintenance,

-

Mechanical design and engineering,

-

Quality control and inspection.

The 3D measurement technologies can also offer a great potential for the medical care sector. They can be used to reduce response times replacing traditional methods and making the process as simple as possible. This can be done with the use of computer-aided design (CAD) and computer aided manufacturing (CAM). This is a brief list of applications that have used 3D scanning technology effectively:

-

Design and manufacture of orthotics and prosthetics,

-

Plagiocephaly treatment,

-

Control of wound healing,

-

Aesthetic prosthetics,

-

Cranial remodeling.

Representations

TECSUD S.A.S. has represented several international technological companies, such as CREAFORM 3D, succeeding in staying ahead in technology.

Manufacturers Collaboration

TECSUD S.A.S. has collaborated with numerous manufacturers of the automotive sector such as:

- Renault,

- Chrysler,

- Bombardier Transportation,

- Bombardier Recreational Products,

- Prevost Car,

- Nova Bus and Mack Truck.

Tecsud S.A.S.

- Calle 31 N° 13A 51, Torre 1, Oficina 210, Bogota, Colombia

- +57 1 359 3997/8

- info@tecsud.com

- www.tecsud.com