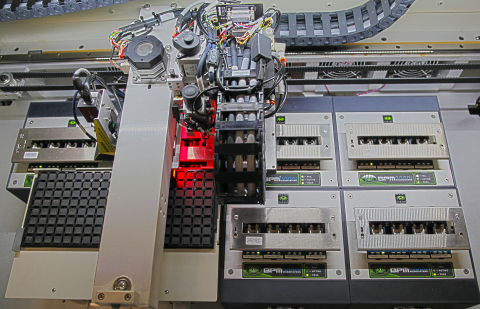

BPM Microsystems Reduces Cost of Programming for 30- to 90-Second Programming Time MCUs and Flash Devices

BPM Microsystems, Inc. today announced it will be demonstrating a mid-sized Automated Programming System (APS) with a 75% increased capacity at Productronica in Munich, Germany— the 3928. Rated at 1,432 Devices per Hour (DPH) and 28 sockets, the 3928 delivers high-volume automotive-level quality and reliability in a small footprint. With 75% greater capacity, vision centering, 9th Gen programming sites, WLSCSP and eMMC support and a base price that starts under $110,000, the 3928 is positioned to outperform higher-priced systems. BPM chose to include standard high-end features such as WLCSP support, universal sites that support eMMC programming, self-teaching, Vector Engine, process integration API and CE Mark. The 3928 supports even complex processes requiring 3D inspection, encryption, serialization, and laser marking.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20191111005713/en/

BPM 3928: The Small Footprint/High Throughput Automated Programmer with 75% More Capacity (Photo: Business Wire)

“By focusing on making our customers highly successful in competitive industries, the engineering team has delivered 75% increased capacity in the same footprint at a lower cost,” says William White, founder and President of BPM Microsystems. “By coupling the 3928’s high throughput with high socket count, the 3928 maintains extremely low cost-per-device for a wide variety of complex MCUs and Flash memories requiring up to 90 seconds to program. The 3928 delivers the best value currently available in device programming.”

“Our customers need the capability and flexibility to program everything from simple MCUs to large eMMC devices on a single machine,” says Colin Harper, Product Manager at BPM. “The 3928 provides a lot of capacity and is highly configurable, including 3D inspection, previously only available with more expensive, large footprint machines.”

The 3928 is easy to set up and use primarily due to WhisperTeach™, one of BPM's award-winning exclusive software features. WhisperTeach™ automatically teaches the critical Z-height with 15-micron accuracy for each pick/place location even for very small packages and saves an average of 83% of the time required for the job setup while increasing yield.

Advanced 3D inspection is available for high-speed device inspection required for automotive/aerospace applications. Peripherals and sites are more configurable than previously possible due in part to advances in 3D printing. On-the-fly vision alignment is achieved with CyberOptics®, maintaining consistent speeds without sacrificing precision. 9th Gen Technology supports over 37,000 devices, over three times more than BPM’s closest competitor.

“For customers with 30- to 90-second programming times, the lower prices combined with increased capacity can cut their total cost of ownership in half compared to previous solutions,” White says.

BPM manufactures its systems in the ISO 9001:2015 certified plant located in Houston, Texas, and carries the CE Mark.

BPM also offers the 3901 for customers who are looking for a sub-$90,000 automated system. If you’re at Productronica, visit Hall A1-353 November 12 through 15, 2019 to see a live 3928 demo. For more information on the 3928, go to bpmmicro.com/3928-7-site-aps/.

View source version on businesswire.com: https://www.businesswire.com/news/home/20191111005713/en/