Palletizing Equipment Market - Drivers and Forecasts by Technavio

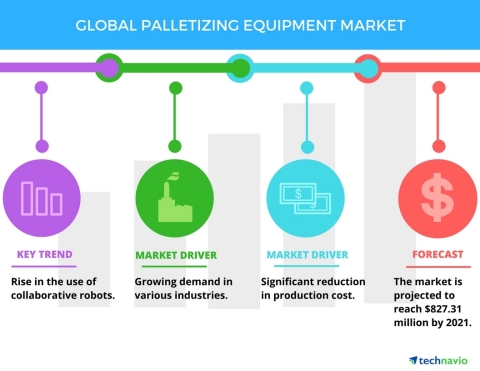

Technavio analysts forecast the global palletizing equipment market to grow at a CAGR of over 4% during the forecast period, according to their latest report.

This press release features multimedia. View the full release here: http://www.businesswire.com/news/home/20171101006413/en/

Technavio has published a new report on the global palletizing equipment market from 2017-2021. (Graphic: Business Wire)

The research study covers the present scenario and growth prospects of the global palletizing equipment market for 2017-2021. The palletizing equipment market has been segmented based on end-user segments, including food and beverages industry, pharmaceutical and personal care industry, chemical industry, and others.

The global palletizing equipment market is expected to showcase a positive growth during the forecast period owing to growth in various industries like the food and beverages, pharmaceutical and personal care, chemical, and others. The demand in these markets will accelerate the adoption of automated systems like palletizers that help in efficient stacking of products at a fast rate, in keeping with the increasing production rates in these industries.

This report is available at a USD 1,000 discount for a limited time only: View market snapshot before purchasing

Buy 1 Technavio report and get the second for 50% off. Buy 2 Technavio reports and get the third for free.

Technavio analysts highlight the following three factors that are contributing to the growth of the global palletizing equipment market:

- Growing demand in various industries

- Better operational efficiency, performance, and flexibility

- Significant reduction in production cost

Looking for more information on this market? Request a free sample report

Technavio’s sample reports are free of charge and contain multiple sections of the report including the market size and forecast, drivers, challenges, trends, and more.

Growing demand in various industries

The economic progress and expanding middle-class segment in various developing countries have triggered growth in the various end-user segments in the food and beverages industry, pharmaceutical and personal care industry, chemical industry, and various other industries. For example, the global packaged food industry is expected to grow by more than USD 3 trillion in 2021, growing at a CAGR of around 5% during the forecast period.

Shakti Jakhar, a lead warehouse and storage research analyst at Technavio, says, “There is a need to deliver the products in an appealing and saleable form to the customers. This requires proper efforts to stack the products on the pallets so that they can be transported safely to the customers. Manual placement of products on the pallets is time-consuming and proves expensive. Manual palletizing was an ideal option when the production scales were moderate. With the increasing number of units produced, better options are required to stack the products on pallets.”

Better operational efficiency, performance, and flexibility

The manufacturers of various industries can have a competitive edge over other players through better productivity and operational efficiency. To gain better operational efficiency, the time consumed in the palletizing process has to be minimized by replacing the workforce with automatic palletizers that have better operational efficiency and also save time and reduces cost. For example, a conventional palletizer can stack 25-40 bags per minute, which might slightly vary based on the model. The increased speed of stacking results in better time utilization and operational efficiency.

“The main factors affecting the operational performance is speed which, in turn, reduces the downtime and improves efficiency. The use of manual placement of products will not provide the required operational efficiency. The automatic palletizers have the ability to operate at different speeds with improved efficacy thus eliminating downtime,” adds Shakti.

Significant reduction in production cost

The introduction of palletizers has an added advantage over manual palletizing in terms of the production cost. One of the major components in the production cost is the wages for employees. Not only hourly wages for the employees but also other associated costs for training, recruiting, and compensation have to be considered. This increases the total production cost of the final product.

The adoption of palletizer equipment plays a major role in the cost reduction in various ways. The introduction of palletizers eliminates the human interference in the palletizing process. The speed of operations reduces the time spend for stacking of products on the pallet. With improved speed, more items can be placed in the pallet quickly and in the desired manner.

Top vendors:

- ABB

- Columbia Machine

- FANUC

- Kawasaki Robotics

- KUKA

Browse Related Reports:

- Global Container Weighing System Market 2017-2021

- Global Horizontal Carousel Market 2017-2021

- Global Warehouse Racking Market 2017-2021

About Technavio

Technavio is a leading global technology research and advisory company. Their research and analysis focuses on emerging market trends and provides actionable insights to help businesses identify market opportunities and develop effective strategies to optimize their market positions.

With over 500 specialized analysts, Technavio’s report library consists of more than 10,000 reports and counting, covering 800 technologies, spanning across 50 countries. Their client base consists of enterprises of all sizes, including more than 100 Fortune 500 companies. This growing client base relies on Technavio’s comprehensive coverage, extensive research, and actionable market insights to identify opportunities in existing and potential markets and assess their competitive positions within changing market scenarios.

If you are interested in more information, please contact our media team at media@technavio.com.

View source version on businesswire.com: http://www.businesswire.com/news/home/20171101006413/en/