Hannibal Industries Reveals TubeRack Cost Savings

Today, Hannibal Industries, one of the leading rack manufacturers, has revealed the cost savings associated with its patented TubeRack product. View the video illustrating the ways TubeRack provides cost savings with figures here: https://youtu.be/dn8EH6o7lnA

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20190409005916/en/

Hannibal Industries Reveals TubeRack Cost Savings (Graphic: Business Wire)

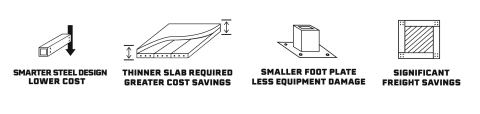

TubeRack’s inventor, Andrew Kirby states, “In addition to safety, TubeRack offers cost savings in its design, reduced concrete slab requirements, smaller footplates minimizing forklift damage and very significant freight savings.”

SMARTER STEEL DESIGN

Steel content costs for many TubeRack designs will be lower than conventional racking while providing even GREATER impact resistance. Steel content is the single biggest cost driver in the manufacturing of racking systems.

REDUCED CONCRETE SLAB REQUIREMENTS

Concrete is expensive. Slab requirements are also significantly different for TubeRack designs, with many designs reducing thickness by up to six inches. A conservative cost savings figure is approximately 12% for every two inches of reduced slab.

SMALLER FOOTPLATES SAVE MONEY ON FORKLIFT REPAIRS

Larger footplates associated with many conventional rack designs can create narrow aisle space for forklift operation leading to tire damage and impact with racking. Tire damage on a typical Outrigger truck can cost up to $600.00 per incident.

FREIGHT SAVINGS:

Traditional racking’s welded diagonals make it impossible to cube out a truck or container. TubeRack’s modular design makes it possible to cube out a truck or container, maximizing the freight. This makes freight savings significant. Typical freight savings based on truck cubing can range from 25%-35% less trucks per project. A 500,000-pound TubeRack project shipping from Los Angeles to Seattle may save $20,000 over conventional racking

For additional information on Hannibal and its product offerings, please visit: http://www.hannibalindustries.com, on Twitter @HannibalRack, on the Hannibal Rack YouTube channel and on LinkedIn.

About Hannibal Industries, Inc.

Hannibal Industries, Inc., headquartered in the Los Angeles metro area, is a pallet rack and steel tube manufacturer with a diverse product line that enables the company to offer material handling products to the most massive operations in the world. This employee-owned company is the largest U.S. manufacturer of steel pallet rack west of the Mississippi River.

The company’s industry leading product offering includes TubeRack, Structural Pallet Rack, Roll-Formed Selective Pallet Rack, Hybrid Systems, Cantilever Systems, Pushback Systems and Drive-In Systems. Engineering and design services offered by the company include: system design; seismic engineering; permit administration; in-house installation and custom fabrication. A true innovator, Hannibal Industries was awarded a patent in 2006 for a pallet rack system adjustable safety restraint, and a patent for its TubeRack in 2015.

View source version on businesswire.com: https://www.businesswire.com/news/home/20190409005916/en/