Westwater’s Coosa Project Graphite Performs Well Over Extended Period Testing

Westwater Resources, Inc. (“Westwater,” or the “Company”) (Nasdaq: WWR), an energy materials development company, is pleased to provide the long-term cycling data obtained by independent tests conducted on coated spherical purified natural crystalline graphite (ULTRA-CSPG) from the Company’s Coosa Graphite Project.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20190415005228/en/

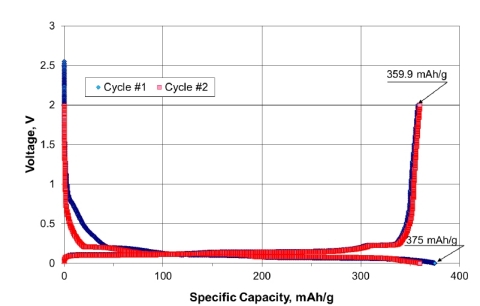

Figure 1. Initial galvanostatic cycling of coated purified spheroidal graphite from Coosa Graphite Project, CR2016 coin cells. Li/Li+ reference. Electrolyte: LP-81 + 5 wt. % vinylene carbonate. C/20 charge-discharge rate. (Graphic: Business Wire)

Christopher M. Jones, President and CEO of Westwater Resources, stated: “We are proud to be among the first in the graphite development space to release long-term cycling performance results of our purified coated natural flake spherical graphite materials from our Coosa Graphite Project. We are not aware of anyone ever to date to report long-term cycling data for U.S. sourced natural flake graphite materials. We are also pleased that the test results showed continued improvements on the irreversible capacity loss compared to tests completed on Coosa ULTRA-CSPG in 2016.”

“The lithium-ion battery market growth we see worldwide is driven by the fast-growing market for electric vehicles. Every major automaker in the world either has an electric vehicle product line, or is considering the development of one. We are excited to be part of this growth, and these positive tests of ULTRA-CSPG mean that we are one large step closer to commercialization.”

As indicated in Westwater’s news release on April 11, 2019, electrode formulation for the half cells utilizing the uncoated spherical graphite (SPG) was optimized and tested. These tests showed positive long-term cycling performance although uncoated SPG is not directly used in battery operations. For lithium-ion batteries, coated spherical graphite like our ULTRA-CSPG is used as an anode material. Westwater’s ULTRA-CSPG is sourced and manufactured exclusively from the Company’s Coosa Graphite Project property, located in Coosa County, Alabama, USA. Testing details are presented below.

HIGHLIGHTS OF THE TEST RESULTS

- Extremely low irreversible capacity loss of 4.03% due to optimized electrode formulation.

- First ever long-term cycling data on U.S. sourced CSPG.

- Very stable cycling performance over 200 cycles.

- Superior performance compared to the leading CSPG originated from China.

TEST SUMMARY

- Purification, micronization, spheronization, classification and surface coating of our natural flake graphite from the Coosa Graphite Project were achieved through the Company’s innovative, proprietary specialty processes. The purity level achieved was greater than 99.95 wt%.

- ULTRA-CSPG grades were formulated into the battery grade coatings and cast on copper foil. CR2016 coin cells were assembled and tested using the graphite as anode versus Li/Li+ counter electrode assembly (half-cell). Low temperature LP81 electrolyte from BASF was utilized in the cells. The upper and lower voltage limits during cycling was 0.01 V and 2 V vs Li/Li+. Charging and discharging current rate was C/20.

- The properties of ULTRA-CSPG from the Coosa Graphite Project are presented in the table below.

| PARAMETER | VALUE (UNITS) | ||||||||||||||||

| TRADE NAME | ULTRA-CSPG | ||||||||||||||||

| LOSS ON IGNITION | > 99.95 (wt%) | ||||||||||||||||

| ASH% | < 0.05 (wt%) | ||||||||||||||||

| SCOTT VOLUME | 0.59 (g/cm3) | ||||||||||||||||

| TAP DENSITY | 0.93 (g/cm3) | ||||||||||||||||

| BET SURFACE AREA | 2.1 m2/g | ||||||||||||||||

| D50 |

18.9 (micrometer) |

||||||||||||||||

- Reversible capacity, irreversible capacity and irreversible capacity loss are the most critical metrics for measuring battery performance. These parameters are obtained after the first charge and discharge cycle. Figure 1 shows the initial galvanostatic cycling results for the first 2 cycles.

| a. | Reversible capacity: 359.9 mAh/g. | ||||||||||

| b. | Irreversible capacity: 375 mAh/g. This is the initial charge capacity. | ||||||||||

| c. | Irreversible capacity loss (ICL): 4.03% which yields 95.97% efficiency. This remarkably low ICL value is achieved by optimization of electrode composition, calendared density, active material loading and electrode formulation. In 2016, the tests performed on Coosa ULTRA-CSPG indicated ICL as 5.09% with 94.91% efficiency. The present formulations improved the ICL value. | ||||||||||

- The long-term cycling tests were performed on optimized formulations and the results are presented in Figure 2. As shown, our ULTRA-CSPG showed stable cycling performance over 200 cycles. The overall reversible capacity reduction of ULTRA-CSPG over the 200+ cycles was estimated as 342.65 / 351.2 = 2.43%. Consistent with commonly accepted conventions of the battery industry, cycling is typically run until 80% of the initial reversible capacity is reached. Stated ultra-low degradation upon prolonged cycling is a very positive sign. This ability to maintain low degradation may enable Coosa material to qualify for use as anodes in batteries with greatly extended cycle life of beyond 1,000 cycles.

- Long-term cycling data was benchmarked against electrochemical performance of leading coated natural spheroidal graphite originated from Hunan province in China. The performance of ULTRA-CSPG exceeded the performance of the Chinese control sample over the 200 cycles.

- These tests were conducted by a leading independent North American energy materials laboratory specializing in research and development on industrial graphite, carbon and batteries.

About Westwater Resources

WWR is focused on developing energy-related materials. The Company’s battery-materials projects include the Coosa Graphite Project — the most advanced natural flake graphite project in the contiguous United States — and the associated Coosa Graphite Mine located across 41,900 acres (~17,000 hectares) in east-central Alabama. In addition, the Company maintains lithium mineral properties in three prospective lithium brine basins in Nevada and Utah. Westwater’s uranium projects are located in Texas and New Mexico. In Texas, the Company has two licensed and currently idled uranium processing facilities and approximately 11,000 acres (~4,400 hectares) of prospective in-situ recovery uranium projects. In New Mexico, the Company controls mineral rights encompassing approximately 188,700 acres (~76,000 hectares) in the prolific Grants Mineral Belt, which is one of the largest concentrations of sandstone-hosted uranium deposits in the world. Incorporated in 1977 as Uranium Resources, Inc., Westwater also owns an extensive uranium information database of historic drill hole logs, assay certificates, maps and technical reports for the western United States. For more information, visit www.westwaterresources.net.

Cautionary Statement

This news release contains forward-looking statements within the meaning of the Private Securities Litigation Reform Act of 1995. Forward-looking statements are subject to risks, uncertainties and assumptions and are identified by words such as “expects,” “estimates,” “projects,” “anticipates,” “believes,” “could,” and other similar words. All statements addressing events or developments that WWR expects or anticipates will occur in the future, including but not limited to statements relating to the future performance of the Company’s coated spherical purified graphite, from the Coosa Graphite Project or otherwise, are forward-looking statements. Because they are forward-looking, they should be evaluated in light of important risk factors and uncertainties. These risk factors and uncertainties include, but are not limited to, (a) the Company’s ability to successfully integrate Alabama Graphite Corporation’s business into its own, and the risk that additional analysis of the Coosa Graphite Project may result in revisions to the findings of WWR’s initial optimization study; (b) the Company’s ability to raise additional capital in the future; (c) spot price and long-term contract price of graphite, lithium, vanadium and uranium; (d) risks associated with our domestic operations; (e) operating conditions at the Company’s projects; (f) government and tribal regulation of the graphite industry, the lithium industry, the vanadium industry, the uranium industry, and the power industry; (g) world-wide graphite, lithium, vanadium and uranium supply and demand, including the supply and demand for lithium-based batteries; (h) maintaining sufficient financial assurance in the form of sufficiently collateralized surety instruments; (i) unanticipated geological, processing, regulatory and legal or other problems the Company may encounter in the jurisdictions where the Company operates or intends to operate, including in Alabama, Texas, New Mexico, Utah, and Nevada; (j) the ability of the Company to enter into and successfully close acquisitions or other material transactions; (k) the results of the Company’s lithium brine exploration activities at the Columbus Basin, Railroad Valley, and Sal Rica projects, and the possibility that future exploration results may be materially less promising than initial exploration result; (I) any graphite, lithium, vanadium or uranium discoveries not being in high-enough concentration to make it economic to extract the metals; (m) currently pending or new litigation or arbitration; and (n) other factors which are more fully described in the Company’s Annual Report on Form 10-K, Quarterly Reports on Form 10-Q, and other filings with the Securities and Exchange Commission. Should one or more of these risks or uncertainties materialize or should any of the Company’s underlying assumptions prove incorrect, actual results may vary materially from those currently anticipated. In addition, undue reliance should not be placed on the Company’s forward-looking statements. Except as required by law, the Company disclaims any obligation to update or publicly announce any revisions to any of the forward-looking statements contained in this news release. The results of the initial optimization study are preliminary in nature and subject to revision following WWR’s further analysis of the Coosa Graphite Project.

View source version on businesswire.com: https://www.businesswire.com/news/home/20190415005228/en/