Desktop Metal and the Korea Institute of Industrial Technology Partner to Accelerate the Adoption of Metal Binder Jetting for SMEs in South Korea

Desktop Metal (NYSE:DM) and the Korea Institute of Industrial Technology (KITECH) today announced a partnership to accelerate the industrialization and adoption of additive manufacturing (AM) in South Korea starting with the installations of the Desktop Metal Shop System™ and Production System™ P-1 platforms.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20211221005388/en/

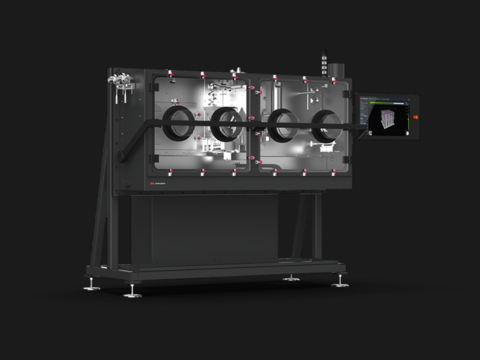

Created by the inventors of binder jetting and single-pass inkjet technology, the Production System is an industrial manufacturing platform powered by Desktop Metal’s patent pending Single Pass Jetting™ (SPJ) technology. It is designed to achieve speeds up to 100 times those of legacy powder bed fusion additive manufacturing technologies and enable production quantities of up to millions of parts per year at costs competitive with conventional mass production techniques. The platform consists of two printer models including the P-1, a solution for process development and serial production applications. (Photo: Business Wire)

KITECH is a leading research institute that facilitates the development of manufacturing technologies for companies across South Korea, with a focus on small and medium enterprises (SMEs). The installation of Desktop Metal’s state-of-the-art binder jet solutions will enable KITECH to help drive adoption of these production-focused technologies with SMEs to address use cases in automotive, consumer electronics, heavy industry, and oil & gas market segments. KITECH plans to leverage Desktop Metal’s solutions to manufacture components at industrial scale volumes and develop new materials for a variety of AM applications.

“We at KITECH are very excited to partner with Desktop Metal on the installation of its industry-leading metal AM solutions,” said Dr. Chung-Soo Kim, Project Manager and Sr. Researcher at the 3D Printing Manufacturing Process Center, KITECH. “Metal binder jetting is disruptive to most other metal AM technologies because of its ability to produce components at unprecedented speeds and low costs. The adoption of binder jetting will change the development environment in the additive manufacturing industry in South Korea.”

“With Desktop Metal’s solutions, we can extend our capabilities beyond the limitations of laser-based additive manufacturing solutions and make significant contributions to the future of key South Korean industries, including automotive, shipment building, oil & gas, and consumer electronics,” said Dr. Dong-Hyun Kim, Head and Principal Researcher at the 3D Printing Manufacturing Process Center, KITECH.

“Metal binder jetting is ripe for adoption in Asia-Pacific, and we are honored to partner with KITECH to further scale the technology in South Korea," said Ric Fulop, Founder and CEO of Desktop Metal. “With our shared vision, the installation of these binder jet solutions will serve as a catalyst for innovation, development and commercialization of AM 2.0 technologies in the region, and accelerate the transformation of the manufacturing industry worldwide.”

Created by the inventors of binder jetting and single-pass inkjet technology, the Production System is an industrial manufacturing platform powered by Desktop Metal’s patent pending Single Pass Jetting™ (SPJ) technology. It is designed to achieve speeds up to 100 times those of legacy powder bed fusion additive manufacturing technologies and enable production quantities of up to millions of parts per year at costs competitive with conventional mass production techniques. The platform consists of two printer models: the P-1, a solution for process development and serial production applications, and the P-50, a large form factor mass production solution for end-use parts. The Production System combines Desktop Metal engineered binders with an open material platform, allowing customers to produce high-performance parts using the same low-cost metal powders used in the metal injection molding industry. An inert processing environment enables compatibility with a variety of materials, including high-performance alloys and even reactive metal powders, such as aluminum and titanium.

Featuring the most advanced single-pass print engine in the binder jetting market, the Shop System offers a turnkey solution for producing complex, end-use metal parts in a fraction of the time and cost of conventional manufacturing and comparably priced legacy AM technologies. The system includes all of the equipment machine shops need to begin binder jetting - from printing through sintering - and is designed to scale throughput with a range of build volume configurations. In addition, Desktop Metal software for build preparation and sintering simulation, in combination with metal powders and process parameters optimized to deliver exceptional part quality and repeatability, make it easy for businesses to get up and running with binder jetting in days instead of weeks or months.

For more information on Desktop Metal’s metal binder jetting technologies, please visit www.desktopmetal.com.

About the Korea Institute of Industrial Technology (KITECH)

KITECH (Korea Institute of Industrial Technology), founded in 1989, endeavors to contribute to the industrial development of Korea by supporting the development and application of production technologies and nurturing global SMEs. We implement technology transfers and dissemination to SMEs, provide technology support utilizing its technology, human resources, and infrastructure, develop technologies to overcome technological hardships experienced by SMEs, and conduct in-depth research for demand-oriented production technologies. For more information, visit https://eng.kitech.re.kr/main/.

About Desktop Metal

Desktop Metal, Inc., based in Burlington, Massachusetts, is accelerating the transformation of manufacturing with an expansive portfolio of 3D printing solutions, from rapid prototyping to mass production. Founded in 2015 by leaders in advanced manufacturing, metallurgy, and robotics, the company is addressing the unmet challenges of speed, cost, and quality to make additive manufacturing an essential tool for engineers and manufacturers around the world. Desktop Metal was selected as one of the world’s 30 most promising Technology Pioneers by the World Economic Forum, named to MIT Technology Review’s list of 50 Smartest Companies, the 2021 winner of Fast Company’s Innovation by Design Award in materials and Next Big Things in Tech Award for sustainability. For more information, visit www.desktopmetal.com.

Forward-looking Statements

This press release contains certain forward-looking statements within the meaning of the federal securities laws. Forward-looking statements generally are identified by the words “believe,” “project,” “expect,” “anticipate,” “estimate,” “intend,” “strategy,” “future,” “opportunity,” “plan,” “may,” “should,” “will,” “would,” “will be,” “will continue,” “will likely result,” and similar expressions. Forward-looking statements are predictions, projections and other statements about future events that are based on current expectations and assumptions and, as a result, are subject to risks, uncertainties. Many factors could cause actual future events to differ materially from the forward-looking statements in this document, including but not limited to, the risks and uncertainties set forth in Desktop Metal, Inc.'s filings with the U.S. Securities and Exchange Commission. These filings identify and address other important risks and uncertainties that could cause actual events and results to differ materially from those contained in the forward-looking statements. Forward-looking statements speak only as of the date they are made. Readers are cautioned not to put undue reliance on forward-looking statements, and Desktop Metal, Inc. assumes no obligation and does not intend to update or revise these forward-looking statements, whether as a result of new information, future events, or otherwise.

View source version on businesswire.com: https://www.businesswire.com/news/home/20211221005388/en/