What’s in cardboard’s future? Smart packaging with self-healing ‘skin’ that repairs itself

In the 150th year of the ubiquitous cardboard box, packaging experts at sustainability leader DS Smith outlined today a futuristic blueprint for how the box might evolve over the next half century.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20221026005758/en/

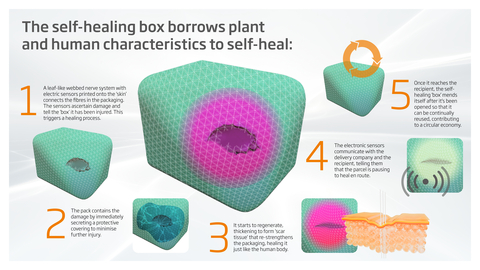

DS Smith outlined today a futuristic blueprint for how the box might evolve over the next half century. Based on trends driven by creative technology, the company’s innovators say they can imagine organic, programmable fibers with the ability to self-heal – like our skin – when damaged. (Graphic: DS Smith)

Based on trends driven by creative technology, the company’s innovators say they can imagine organic, programmable fibers with the ability to self-heal – like our skin – when damaged.

Among the possible characteristics of the self-healing box:

- A webbed nerve system that borrows from the composition of leaves: Sensors are printed onto the “skin” of the box and connect all fibers in the packaging so that it can ascertain damage and communicate externally.

- Regenerative “scar tissue:” Healing itself just like the human body, the surface stretches and thickens to cover the injury. It then transmits data to the delivery company and the recipient to tell them it is pausing to heal itself en route.

- Reuse capability: After it has been opened, the packaging heals the opening of the pack so that it can be continually reused, extending its life.

“We’ve seen all around us technologies making life easier and more efficient,” said Melanie Galloway, vice president, sales, marketing, innovation, DS Smith. “Packaging that heals itself so it can be perpetually reused is, of course, a futuristic concept, but it’s rooted in our efforts to design out waste and support the reuse of materials. So, a broader a circular economy in which materials stay in use for much longer, may be closer than we think.”

Looking into its storied past as well as into its evolutionary future to mark the 150th year of the cardboard box, DS Smith has created a retrospective of corrugated cardboard, charting how it has woven its way through society.

The new digital archive celebrates past and present achievements in the race for innovative ideas, such as plastic replacement designs like Eco Carrier and parcels that can withstand cold and wet conditions, such as Greencoat. The historical highlights include:

1600s: The cardboard box is born, but not as we know it. Taking its roots from 16th century fashion, the construction of ruffled lace collars is to inspire the corrugating of paper for cardboard centuries later.

1871: American Robert H. Thompson patents machinery to produce corrugated board in 1882 to wrap glass bottles and becomes the grandfather of the modern corrugated industry. Ultimately, he begins the cardboard revolution that will lead to the birth of the box.

1886: The jeweler Tiffany introduces its eponymous ring setting and creates the original patented blue ring box. The box is synonymous with the brand, becoming one of the most recognizable in history. Admirers visit the store in New York requesting to buy the boxes. They are refused unless they buy a ring to go with it.

1939: World War II begins, and gas masks are issued across Britain in cardboard boxes. It is a legal requirement to always carry them. The boxes foster rivalry among school children, and kids make their own modifications to personalize their gas mask box.

2020: The UK is the first country to begin a vaccine rollout and the project is the largest national immunisation program in history. The DS Smith team helps transport the first vaccines in the UK and then worldwide to hospitals and clinics in cardboard boxes.

In addition to the self-healing box blueprint, innovators at DS Smith also expect to see developments in the fields of self-adjusting parcels and spray-on packaging.

Galloway said she expects to see intelligent packaging that self-adjusts its size to fit its contents, making efficient use of materials and space.

“Some of these ideas are still are not here yet, but we must continue to press ahead with the next set of innovations to help us use materials as sustainably as possible. That will be achieve this with fresh thinking and creative approaches,” she said.

About DS Smith

DS Smith is a leading provider of sustainable fiber-based packaging worldwide, which is supported by recycling and papermaking operations. It plays a central role in the value chain across sectors including e-commerce, fast moving consumer goods and industrials. Through its purpose of ‘Redefining Packaging for a Changing World’ and its Now and Next sustainability strategy, DS Smith is committed to leading the transition to the circular economy, while delivering more circular solutions for its customers and wider society – replacing problem plastics, taking carbon out of supply chains and providing innovative recycling solutions. Its bespoke box-to-box in 14 days model, design capabilities and innovation strategy sits at the heart of this response. Headquartered in London and a member of the FTSE 100, DS Smith operates in 34 countries employing around 30,000 people and is a Strategic Partner of the Ellen MacArthur Foundation. Its history can be traced back to the box-making businesses started in the 1940s by the Smith family. North American operations are based in Atlanta, with 15 manufacturing, paper and recycling facilities, totaling more than 2,000 employees. DS Smith will report annually its progress across its climate targets in its Sustainability and Annual Reports.

View source version on businesswire.com: https://www.businesswire.com/news/home/20221026005758/en/