Categories

- Mechanical, Electro-mechanical, Hydraulic and Pneumatic components

TAT Technologies, Ltd. is a diversified technology-based engineering and industrial company specializing in design, development and manufacture of Heat Exchangers, Cooling Systems, Cold Plates, Vapor-Cycle Air Conditioning Systems (for both military land applications and airborne applications) and Fuel Systems, etc. Another facet of our activities is manufacture and overhaul of Secondary and Emergency Power Systems for F16, Jet Fuel Starters for F16, Fuel Controls, Turbines and Valves etc. We also design and manufacture Air Conditioning and NBC Systems for military and civil applications such as communication & military shelters, armored vehicles in various configurations for custom applications. The company employs about 180 employees.

SUBSIDIARIES

Bental Industries Ltd. is a leading design & manufacturing company in the field of power & motion components and systems for land and air defense platforms. Bental designs products which are based on the company's comprehensive line of onboard integrated solutions for AFVs, missiles, satellites and UAVs including sophisticated servo motors, servo actuators, cutting-edge propulsion systems, alternators and starters, and mini stabilized payload systems of surveillance application. Bental is located in the northern part of Israel and employs about 110 employees.

Piedmont Aviation Component Services Inc., located in Kernersville (near Greensboro), North Carolina, USA is a wholly owned subsidiary of TAT. Piedmont Aviation Component Services offers extensive component maintenance and overhaul capability for the commercial, regional, corporate and general aviation industry. Piedmont is a FAA and EASA Part 145 Repair Station with nearly 60 years of experience in propeller and landing gear overhauls, and over 20 years of experience in Honeywell (formerly Allied Signal) auxiliary power units (APU) and related component overhauls. Piedmont's Aviation Parts Services Division maintains a full complement of items, including Line Replaceable Units (LRU), Components and Piece Parts for Commercial, Regional, Corporate and General Aviation aircraft. Employs about 120 employees.

Limco-Airepair, Inc. Located in Tulsa, Oklahoma, U.S.A. is a wholly owned TAT subsidiary in U.S.A. The company is active in design and manufacture of heat transfer equipment for aerospace applications. Being an FAA/EASA approved Repair Station, this Company repairs and overhauls Heat Exchangers and ducting for Air Systems, Engines and APU's for military and civil aircraft applications. Employs about 140 employees.

Aerospace Products International, is a partialy owned subsidiary (37%) of TAT located in Memphis, TN. API is the aviation industry's leading provider of parts and innovative distribution and supply chain management solutions. As a subsidiary of First Aviation Services Inc., API has a proud history of providing exceptional service to aircraft operators, manufacturers and MRO providers. Our leadership group's knowledge and understanding of the aviation business is unparalleled. As a result, API has quickly become the top destination for aviation supply chain experts to build their careers

PARENT COMPANY

KMN Holdings

KMN Holdings is one of the leading public companies in the Israeli economy. KMN invests in leading companies with high growth potential that are engaging in trade, industry and investments in Israel and abroad, and focuses on strategy planning and synergy among them.

TAT Technologies is ISO 9001, AS 9100, ISO 14001:2004 and OHSAS 18001:2007 certified.

Air to Air Heat Exchangers

TAT is a world leader in development and manufacture of "Fin-and-Plate" Heat Exchangers for airborne and other applications. Our innovative Heat Exchangers are well-known for their superior performance with gas and liquid and mixed-phase flow media.

TAT Heat Exchangers are manufactured from Aluminum and Nickel-based alloys to cover virtually any operating temperature requirement. TAT carries ongoing R&D efforts to investigate applicability of new construction materials and their combinations.

Our Heat Exchangers are installed on a variety of military (F-15, F-16, etc.) and civil (A340-500/600, CRJ-700/900, etc.) aircraft.

Liquid & Dual Phase Heat Exchangers

TAT Technologies has a large experience in the field of Oil Coolers for over 25 years. We are the manufacturers of Airborne Oil Coolers for a wide variety of applications: Turbo Jet hydraulic systems, Helicopter Gear Boxes, Aircraft Piston Engines and more. At TAT Technologies we make all types of Fin & Plate Oil Coolers - Air/Oil, Fuel/Oil and Water/Oil.

TAT Technologies is an innovator in the field of Oil Coolers and has unique products for which we have patent pending like the breakthrough MonoBlock.

Among our customers you will find some of the world leaders such as Boeing (F-15, V-22, 737, 767), Safran Group - Hispano-Suiza, Hamilton APU's, Pilatus Aircraft and more.

Cold Plates and Antennas

This line of TAT products is versatile and impressive in terms of both engineering and technological challenges. Our unique Cold Plates are used for cooling power electronics by means of gas, fluid and phase-changing materials and are literally tailor-made to meet any requirement, however daunting.

Only TAT vast experience in the field coupled with unquestionable prowess of our engineering and production teams can produce a state-of-the-art Cold Plate at an unbeatable price and lowest weight.

As for the clients, such prestigious companies as Thales, Rafael, IAI-Elta, Elbit, LIG Nex1 and others have been entrusting TAT with their most sensitive applications over many years.

Cooling Systems

Another facet of TAT activities worth honourable mention is engineering and production of dedicated self-contained Cooling Systems of modular design for power electronics. Such Systems typically incorporate various flow control devices such as pumps and valves along with most efficient heat exchangers. The winning combination of low weight and superior performance is achieved by multi-year TAT expertise, all under one roof. Our continued success with such demanding clients as Elta and Elisra attests to TAT maturity and competence.

Talking of Cooling Systems, TAT is also proud to offer its Environmentally Friendly Air Conditioning System (EFACS), an environmental control unit for electronics or personnel. The System is based on high-speed, self-propeller Air Cycle Machine and its possible applications are diverse and fascinating, be it a pod or a manned vehicle.

Aircraft ECS

TAT designs and develops advanced 28VDC and 400Hz AC Vapor Cycle Cooling Systems (VCCS) for used on Helicopters and Business Jet Aircraft both for Military and Commercial applications. Our VCCS can be designed as FAA Supplemental Type Certificate (STC) and also as a solution for OEM Aircraft manufacturers.

Our goal is to design and produce a truly integrated and efficient VCCS which demands and provides superior passenger comfort while minimizing weight, drag and cost. In order to achieve this goal we are constantly looking to used in our designs advanced components which are available in the market such as fin-plate heat exchangers, brushless motor, efficient electrical variable speed motors, advanced compressors etc.

Military Air Conditioning

The field of Military Air Conditioning Systems has earned TAT a reputation of supplier of highly reliable and affordable equipment remarkable for its performance and simplicity. TAT manufactures a comprehensive line of AC Systems for any application where heat removal is essential. Simple installation, maintenance and easy integration make our systems user-friendly. All our Systems meet the requirements of applicable Military Standards (MIL-STD-810, MIL-STD-461) and serve around the world in extreme conditions. Our Air Conditioning Systems are typically installed on Military Communication Shelters, Mobile Shelters, Military Tents, Armoured Vehicles, etc.

Flow Control Accessories & Power Systems

No list of TAT capabilities is complete without mentioning the vast experience we have accumulated over many years in design and manufacture of Flow Control Accessories. In this field, TAT is a single address for all your "Built-to-Spec" and "Built-to-Print" needs.

Full engineering and manufacturing capability of TAT with regard to Flow Control Accessories has repeatedly proved itself in such ingenuously developed hardware as Bleed Air Valves, AC & DC Pumps, Float Valves, Gate Valves, Fuel Flow Proportioners, Fuel Drop Tank Valves, etc. These can be found on both military (F-15, F-16, F-18, T-50) and civil (Galaxy) aircraft.

TAT is also manufacturing the Emergency Power Unit for F-16 aircraft under license with perfect record.

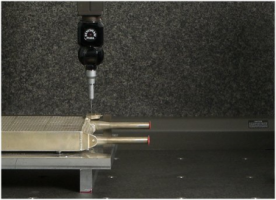

FIN FORMING

A plate-fin heat exchanger is a type of heat exchanger design that uses plates and finned chambers to transfer heat between fluids. It is often categorized as a compact heat exchanger to emphasise its relatively high heat transfer surface area to volume ratio.

The plate-fin heat exchanger is widely used in many industries, mainly the aerospace industry for its compact size and lightweight properties, as well as in cryogenics where its ability to facilitate heat transfer with small temperature differences is utilized.

SHEET METAL

Our sheet metal department supports all activities in the brazed parts manufacturing that require welding and sheet metal working.

In our Sheet Metal Departments, we employ the most experienced and skilled sheet metal workers and welders one can find in the field to make sure that TAT remains at the forefront.

BRAZING

Furnace brazing is a semi-automatic process used widely in industrial brazing operations due to its adaptability to mass production and use of unskilled labor. There are many advantages of furnace brazing over other heating methods that make it ideal for mass production.

One main advantage is the ease with which it can produce large numbers of small parts that are easily jigged or self-locating. The process also offers the benefits of a controlled heat cycle (allowing use of parts that might distort under localized heating) and no need for post braze cleaning. Common atmospheres used include: inert, reducing or vacuum atmospheres all of which protect the part from oxidation. Some other advantages include: low unit cost when used in mass production, close temperature control, and the ability to braze multiple joints at once. Furnaces are typically heated using either electric, gas or oil depending on the type of furnace and application. However, some of the disadvantages of this method include: high capital equipment cost, more difficult design considerations and high power consumption.

LEAK & PROOF TESTING

TAT Test Facilities match the diversity of our products and meet the requirements of MIL-STD-810 and RTCA/DO-160D.

Pneumatic and hydraulic equipment as well as heat transfer equipment and a host of valves can be tested on the premises in a wide range of test conditions.

Special test benches have been set up for Hydrazine equipment, Air Conditioning Systems, Engine Starters and Secondary Power Units.

Whenever a special test bench is required, it is designed and manufactured in house by our Engineering Departments in order to ensure accuracy and validation of the test.

QUALITY ASSURANCE

Ensuring top quality of products and service is a cornerstone of TAT philosophy.

As quality-minded company, TAT is certified to AS9100 Rev. B and ISO 9001:2000.

Our Quality Management System is fully documented in Quality Manual and is regularly audited and approved by leading aerospace and military entities throughout the world including Lockheed Martin, Boeing Co., Israel Aircraft Industries, Liebherr-Aerospace, Cessna Aircraft Co., Israel Air Force, U. S. Air Force and Navy, Teledyne, Honeywell Aerospace, General Electric Corp. - Engine Div., etc.

TAT Technologies Ltd.

- Re'em Industrial Park, P.O. Box 80, 70750, Gedera, Israel

- +972 8 8628500

- +972-8-8621555

- tat@tat-technologies.com

- www.tat-technologies.com