Categories

- Aircraft, Helicopter, UAV, Spacecraft & related equipment

- Engines, Propulsion, Power Generation

- Maintenance Repair Overhaul and Logistics Support

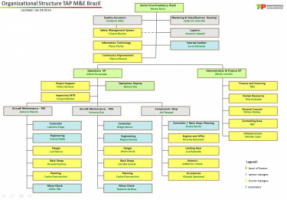

TAP M&E (Maintenance & Engineering) - Brazil Unit, has more than 80 years of experience in operations for big national and international airline companies. The company also known as TAP M&E is controlled by TAP Portugal Group since November 2005 and in January 2009 it was transformed to a subsidiary.

The technological infrastructure and the range of knowledge accumulated over the years have placed the Company in between the (10) largest aircraft and component maintenance, repair and overhaul (MRO) companies in the world.

TAP employs more than 2,000 professionals distributed among its two large Maintenance Centers: in Rio de Janeiro and in Porto Alegre, along with numerous of specialized shops and calibration laboratories. The Company's services are also certified by main aeronautical authorities as: the ANAC in Brazil, FAA, in United States, EASA, and in Europe.

The Company has a capability list of more than 11,000 items, and is certified for the entire line of Boeing - 727, 737, 737NG, 747-100/-200/-300, 757, 767, 777, BBJ; MD11 and DC10; Embraer EMB 120, ERJ 135, ERJ 145, Legacy 600, EMBRAER 170, EMBRAER 175, EMBRAER 190, EMBRAER 195; and the Airbus A300, A300-600, A310, A320, A330 and A340.

It serves dozens of clients from all over the world to carry out aircraft maintenance and conversion in Brazil, generating millions of dollars in foreign currency for the Country.

TAP M&E - Brazil Unit's objective is to perform engineering and maintenance services on aircraft and their components with a high level of quality and punctuality, with competitive schedules and prices in relation to the international market and according to the requirements of the aeronautical authorities, seeking to exceed the expectations of its customers and shareholders.

Contact info #1

Maintenance of Aircraft Engines

TAP Maintenance and Engineering has the necessary instrumentation and a professional team able and certified to carry out the maintenance on following engines:

-

Pratt & Whitney Canada: PW118/A/B, PW120/A, PW121, PW125B, PW127 and PT6A.

-

Pratt & Whitney - Hartford: JT-8D - HSI.

-

Rolls Royce: T56 (OVH).

High capacity for overhauling accessories for these engine families. Works on parts repair using plasma spray, shot peening and TIG welding, amongst other high technology processes.

| Additional Services | Applicability | |

|

CFM-56-3 Series |

Advanced Test Benches in Avionics

TAP Maintenance and Engineering's costumers can count on the largest group of avionics shops in Latin America. In more than 390,000 m² built area, all electro-mechanical aircraft components are repaired, with the most advanced test benches and precision equipment - ATE 900, Iris 2000, ITS 700 and STS 1000 test benches.

In addition, there's one of the most advanced technologies in Computer Automatic Tests: the ATEC- 6000, by EADS Test and Services, which enables the company to carry on tests and repairs, in avionics of next generation aircraft, like Boeing B737-700/800/900 and B777-200/300, the Airbus A320/A330/ A340 fleet.

Negotiations of ATEC-6000 third phase are already advanced. In this phase there will be included adapters capable to test and repair avionics units of latest generation military aircraft, as the CL295 and the Orion-P3, recently acquired by FAB - Brazilian Air Force.

It has began the operation of the EGPWS (Enhanced Ground Proximity Warming System) test and repair bench – which performs tests and repairs on Mark V and Mark VII components of commercial airplanes.

Specialized Shops

Radar and Communications Shop: performs services on radio and transmission equipment systems, like VHF, HF, radars, aerials, transponders, radio-altimeters, EHSI, EADI and Sony and Matsushita in-flight entertainment systems.

Navigation Shop: works with long-distance (INS, Omega, IRS), and short distance (ADF, VOR, ILS) inertial navigation systems plus position management (TCAS) systems.

Instruments Shop: repairs electromechanical systems (altimeters, speedometers, gyroscopes, HSI, ADI – Air Data Instruments and others), INUs (Honeywell and Litton), automatic pilots, FMS (Honeywell, Smiths) and CVR (cockpit voice recorder) and FDR (flight data recorder) recorders.

Electrical Accessory Shop: performs maintenance services on equipment forming part of the electric actuation systems of the aircraft: generators, actuators, switchers, relays, ovens, landing lights and other similar equipment.

Control and Sensor Shop: handles control generator systems, anti-skid systems, sensors/flight control, batteries and chargers and control panels.

Aeronautical Maintenance Training for Staff & Clients

TAP Maintenance and Engineering offers to its customers, dozen courses on the the most up-to-date practices in aeronautical maintenance, the same it frequently trains its technicians and engineers staff. The courses are offered at TAP M&E Brazil's facilities, in Rio de Janeiro and Porto Alegre Maintenance Centers and in Company.

Available Courses

-

General Familiarization,

-

Servicing,

-

Ramp and Transit,

-

Line and Base Avionics Systems,

-

Line and Base Electrical, Airframe, and Powerplant Systems,

-

Run Up,

-

Troubleshooting,

-

Others related to professional training and qualification.

APUs Maintenance

The Company houses the largest and more complete Auxiliary Power Units - APUs in Latin America. Shop's capabilitiy includes the folowing units:

Honeywell - GTCP85 (series) (OVH), GTCP331-200ER (OVH), GTCP36-150A/AA (OVH), GTCP131-9B (OVH), GTCP660-4 (OVH) and TSCP700 (OVH).

Hamilton Sundstrand - APS500 [T62-T-40C11] (OVH). TAP M&E Brazil is finalizing the process to include on its capabilities Honeywell's GTCP131-9A, used on the B737NG and A320 family. It repairs parts by using such technologies as plasma spray, shot peening and TIG welding, amongst other processes.

Certified for the following aircraft: B727, B737, B737NG, B747, B757, B767, EMB120, ERJ 135, ERJ145, EMBRAER 170, EMBRAER 190, D10, MD11, A300, A310, A330 and A340.

Overhaul & Repair of Landing Gear

This shop carries out overhaul and repairs on the structural parts of the landing gears, like the fixing and actuating systems including the parts that, together with the wheels and tires, make up the landing gear units for the following aircraft: B727, B737, B737NG, B747, B767, BBJ, DC10, MD11, EMB120, ERJ145, F50 and ATR4, Military Gears C-130, KC-135 and A320 partial capability.

Here the Griffon GTW-U3 milling machine and Geminis GE-1600S lathe are used, latest generation equipments, which enable any aircraft landing gear units to be repaired performing the following services:

-

Dismantling, cleaning and paint removal (plastic media),

-

Dimensional inspection assembly and testing,

-

Overhaul individual pieces,

-

Inspection of steel parts by overheating – etching,

-

Surface hardening of steel parts – shot peening,

-

Non destructive tests: inspection with magnetic particles, penetrating liquids, eddy current,

-

X-rays and ultrasound.

Components Shops

TAP Maintenance and Engineering owns the largest and most complete group of aircraft shops in Latin America, whose Capability List has more than 17,000 items. It carries out services in all fields of maintenance, repairs and overhaul of aircraft and components:

-

Avionics,

-

Engines & APUs,

-

Hydraulics, Oil & Fuel, Pneumatics and Wheels & Brakes,

-

Landing Gear, Mechanical Components and Painting,

-

Metal and Composite Structures,

-

Interiors and Emergency Equipment.

It has strategic partnerships with companies like Honeywell, Northrop-Grumman-Litton, Sundstrand and Goodrich among others, makes TAP M&E Brazil an Authorized Repair Center of its components.

Clients

The Company's local clients are:

- Avianca,

- Azul,

- Embraer,

- Forca Aerea Brasileira,

- Gol,

- Marinha,

- Brava,

- Passaredo,

- RIO,

- Safra,

- Tam,

- Total,

- Trip,

- Varig,

- Webjet,

- Whitejets.

The Company's International List of Clients includes:

- Abx Air,

- Aer Cap,

- Aerolineas Argentinas

- International Aerospace Group Corp.

- Air Atlanta,

- Air Canada,

- Air Europa.com,

- Air Italy,

- Air Transat,

- Alitalia,

- ATE Jordan Aviation,

- AviancaTaca,

- Aviation Capital Group,

- Awas,

- BOA,

- Boeing,

- Centurion Air Cargo,

- Cielos Airlines,

- Copa Airlines,

- Euro Atlantic,

- FedEx,

- Fuerza Aerea de Chile,

- Fuerza Aerea Uruguay,

- GE Capital,

- Israel IAI,

- ILFC,

- LAM,

- LAN,

- Macquarie,

- SATA,

- sojitz,

- TAAG,

- Tap Portugal,

- THAI,

- UIA,

- White.

TAP M&E (Maintenance & Engineering) - Brazil Unit

- Estrada das Canarias, 1862, Block 2, 21941 480 , Rio de Janeiro (RJ), Brazil

- (+55) 21 3383 2782

- www.tapme.pt/Pages/Default.aspx