Categories

- Aircraft, Helicopter, UAV, Spacecraft & related equipment

WINNSTAL, was founded in 1998 in Sao Jose dos Campos, 90 km (56 miles) from Sao Paulo city and 300 Km (187 miles) from Rio de Janeiro. The company operates in its new facilities, with 3200-square-meters (34.500 square feet) of built area and equipped with the necessary resources to assist the industrial technologies of structural, mechanical, hydraulical, pneumatical and electro-electronic items.

Overview

The Company’s main activities include among others:

-

Maintenance of mechanical and structural aircraft systems.

-

Project Development.

-

Assembling of structural Parts, assemblies and Sub-assemblies.

-

Tooling.

-

Development and Production of Prototypes and tools.

-

Milling of parts CNC process.

-

Manufacturing and Maintenance of Aircraft wiring and cabling.

-

Surface treatment and cabin painting.

-

Production of parts.

-

Maintenance and repair of electrical aircraft system.

-

Stamping and bending of Aluminium pieces.

-

Cut of raw material by Flow System.

-

Production follow-up and inspection of parts.

Vision: To be acknowledged as a reference in the manufacturing of aeronautical parts in the Brazilian market and globally, committed to the quality of its products and services.

WINNSTAL's BUSINESS: Development, parts manufacturing and provision of high complexity services on time and at competitive prices.

SERVICES INCLUDE

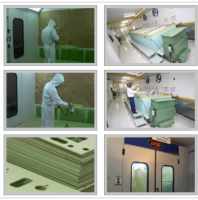

• Manufacture of metallic parts using steel, aluminum and titanium; • CNC Milling machine with 3 axes, milling lathe and conventional machining; • Assembling structural sets and subsets ; • 3-D measurements up to 1.800 mm; • Surface treatment and painting of parts and sub-assemblies; • Design, development and manufacture of tooling and devices for stamping and milling. • Storage, management and cutting of raw material Stamping WINNSTAL manufactures parts in stamping machines and devices using materials like as aluminum, steel and titanium. WINNSTAL is a company with a highly qualified expertise and last generation equipment, capable of developing manufacturing processes with varied levels of complexity and size of parts. Machining WINNSTAL manufactures parts on last generation 3 axes milling machines, milling lathes, conventional machines, and uses software capable of developing manufacturing production processes using modern. This makes production easy and ensures quality and precision. Assembly Among the multitude of services performed by the WINNSTAL is the assembling structural sets and subsets, including: riveting and sealing. Special Processes The company has a Special Processes Area that includes superficial treatments with Alodine 1200, Passivation and Painting of parts and subsets. Tooling WINNSTAL has the ability to design, develop and manufacture tooling to customers specifications from electronic design data (CAD-CAM Programs and NX, Solid Edge e IGMES Versions Softwares). These tooling and devices can be used in stamping and machining processes, as well as in assembling of structural sets and subsets. Raw Material WINNSTAL provides storage, management and cutting of raw material for customers.

COMMERCIAL CLIENTS

- EMBRAER

- AERNNOVA

Winnstal

- Endereco, Rua Miracema, 370, Bairro Chacaras Reunidas, Cidade, Estado de Sao Paulo, CEP 12.238 360, Sao Jose dos Campos, Brazil

- +55 12 2139 9700

- www.winnstal.com.br