Categories

- Mechanical, Electro-mechanical, Hydraulic and Pneumatic components

INDUSTRIAS TANUZI S.A., is a company of the metal mechanical sector with more than 35 years of experience in the design and manufacture of spare parts and the maintenance, upgrade and overhaul of high quality industrial machinery.

Through the years, seeking to satisfy the expectations of its clients in terms of added-value solutions, INDUSTRIAS TANUZI S.A. has gradually upgraded its conventional machinery with the adoption of CNC and welding equipment, in order to optimize production and ensure maximum precision, product quality and competitiveness.

INDUSTRIAS TANUZI S.A. relies on equipment of the latest technology, namely:

-

CNC Centers,

-

CNC rolling machines,

-

Horizontal boring machines (for pieces up to 16 tons),

-

Conventional rolling machines,

-

Milling machines,

-

Radial drills,

-

Plasma equipment,

-

Welding equipment,

-

SolidWorks 2007 software for the design of machinery and parts.

Contact info #1

Maintenance & Repair Services

INDUSTRIAS TANUZI S.A. provides maintenance and repair services on transmissions for different machinery, as well as sprockets, shoe track pads, elevating systems for packaging machines, liquor bottling machines and vertical and multistage pumps with the support of advance machinery and experienced engineers.

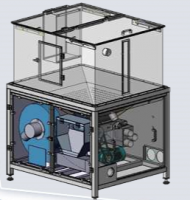

Bottle Washing Machine

An electromechanical system for the washing of glass and plastic bottles, equipped with a conveyor belt and nippers or clamps of flexile material which firmly hold onto the bottles by the neck during the washing process in order to prevent any damages.

This system prevents non-alignment and ensures that bottles are in place during the washing or unloading process. Through a mechanical command, the bottles are sprinkled with sterilized water to eliminate any source of contamination.

The Tanuzi bottle washing machine has an automatic operating system and variable speed controllers, which synchronize the washing parts for the continuous feeding of bottles.

Cap Producing Machine

Automated Cap Producing Machine:

- Storage Capacity: 20.000 caps,

- Speed: 800 caps/minute.

Cap Producing Machine with Magnetic Basic Transporter:

- Storage Capacity: 130.000 caps,

- Speed: 800 caps/minute.

Cap Producing Machine with Magnetic Double Transporter:

- Storage Capacity: 120.000 caps,

- Speed: 1.600 caps/minute.

Pneumatic Transporter for Bottle Caps

INDUSTRIAS TANUZI S.A. is a leader in the bottling industry in Colombia, in the manufacture, repair and installation of pneumatic transporters for plastic caps.

INDUSTRIAS TANUZI S.A. manufactures and repairs pneumatic transporters for bottle caps, which include a storage compartment capable of storing up to 120.000 caps. The bottle caps may exit the storage compartment through the use of electromagnetic vibrators or a conveyor belt.

Magnetic Transporter for Bottle Caps

INDUSTRIAS TANUZI S.A. manufactures magnetic transporters for bottle caps designed according to clients’ technical requirements, consisting of three main compartments:

-

The chute or main storage space,

-

The magnetic elevator,

-

The horizontal transporter.

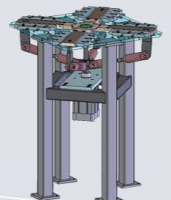

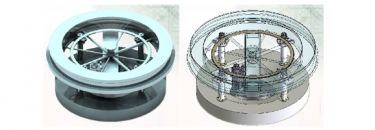

Palletiser

INDUSTRIAS TANUZI S.A. manufactures and installs palletisers for PET bottles. The Tanuzi PPT01 palletizer packages and stacks bottles into blocks to later position them, layer by layer onto a stack or full pallet.

The system’s production level reaches a maximum of 480 caps/hour and is supported by automated mechanical systems, a FESTO pneumatic system and a power system with SEW Eurodrive engines.

Package Sealing Machine

INDUSTRIAS TANUZI S.A. manufactures package sealing machines, a type of automated assembly-line product packaging system, commonly used in the food packaging industry. The machine is activated by a pneumatic system which moves a set of sealing bar clamps that move across the bottom edge sealing the film.

The machine parts are made of high carbon steel and the moving parts are manufactured in bronze to provide maximum durability.

This equipment was developed as an answer to the needs of the packaging industry as it provides greater manoeuvrability during the whole process.

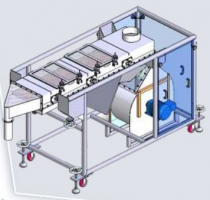

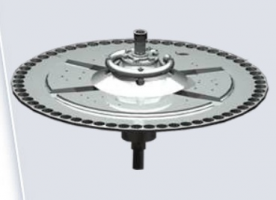

Vibrating Sifter

INDUSTRIAS TANUZI S.A.’s vibrating sifter is manufactured in carbon steel. The main sifter, made entirely of stainless steel to guarantee a more hygienic operation of the machine, sits on spring-like systems.

Its function is to rapidly decrease the temperature of the polymer material handled by reducing it into a pellet form. The product through a funnel ends up in a chamber below, where it is subjected to cold air by a turbine and shaking by two vibrating elements thus, further reducing the temperature.

Spare Parts

INDUSTRIAS TANUZI S.A. manufactures spare parts for industrial machinery, such as:

-

Formapack dies, which are necessary for packaging of cookies and are made of a highly strong and resistant material.

-

Wafer irons for wafer-type cookies.

-

Speed Variators: Electromagnetic systems made of gears, which is used to induce speed variation in magnetic packaging machines.

-

Custom made pieces on which the elevating pistons of a bottling machine are assembled.

Cookie Filling System

INDUSTRIAS TANUZI S.A. manufactures, repairs and installs cookie filling systems that comply with the technical requirements imposed by the industry. The cookie filling systems are used to apply the cream filling to the cookies, through a pump system.

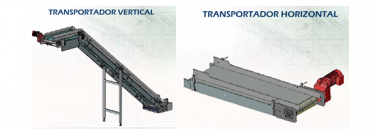

Horizontal & Vertical Conveyor Belts

INDUSTRIAS TANUZI S.A. manufactures conveyor belts for the food industry that can be horizontal or vertical, according to clients’ requests. These conveyor belts may possess retractable parts and can be made of plastic to facilitate metal detection and the removal of harmful materials.

Bag Sealing Machines

INDUSTRIAS TANUZI S.A. manufactures bag sealing machines for the food industry, ideal for the sealing of liquids, such as water, milk and drinks in plastic bags. INDUSTRIAS TANUZI S.A. has the capacity to manufacture, repair and install bag sealing machines for different sizes of bags.

Capabilities

The design department of INDUSTRIAS TANUZI is equipped with software of the latest technology, such as CAD-CAE and Solidworks and has the support of a competent and qualified team of engineers, experimented in different engineering tasks. Among the Company’s personnel are mechanical engineers, mechatronic engineers, industrial designers and mechanic electricians. This is an interdisciplinary team of professionals that offers high quality solutions to clients in the bottling, energy, mining and oil tanker industries.

Machine Park

| Vertical Machining Center | Mazak | x:1120 y:410 z: 510 Max Weight: 550 Kg |

| Machining Center | Leadwell | x:1020 y:510 z: 610 Max Weight: 550 Kg |

| Horizontal Boring Machine | Tos | Length/Width of bed 3000 x 2000 Max Weight: 5 Tons |

| Horizontal Boring Machine | Tos | x:4000 y:1800 z: 1500 Max Weight: 16 Tons |

| Portable Boring Machine | York | Weight 420 rev/min, L = 400 mm, D= 1" - 1 1/2" |

| Milling machine | Tos | Length/Width of bed 1250 x 400 |

| Milling machine | Tos | Length/Width of bed 1005 x 400 |

| Milling machine | Tos | Length/Width of bed 600 x 400 |

| Drilling milling machine | Imatmill | x:600 y:250 z: 300 weight Max: 250 Kg |

| Horizontal CNC Lathe | Mazak | Length/Width of bed: 400mm Swing over bed: 250mm |

| Horizontal CNC Lathe | Shen Yang | Length/Width of bed: 1390mm Swing over bed: 610mm |

| Lathe | Sofia | Length/Width of bed: 2000 Swing over bed: 500 mm |

| Lathe | Tarnow | Length/Width of bed: 3000 Swing over bed: 680 mm |

| Lathe | Shen Yang | Length/Width of bed: 1500 Swing over bed: 400 mm |

| Lathe | Shen Yang | Length/Width of bed: 3000 Swing over bed: 800 mm |

| Lathe | Shen Yang | Length/Width of bed: 3000 Swing over bed: 2000 mm |

| Radial Drill | Dar Sin | 500 mm Spindle head travel 750 mm |

| Radial Drill | Dar Sin | 500 mm Spindle head travel 900 mm |

| Plasma Cutter | Miller | Cuts up to 1 1/4" |

| MIG Welding Machine | Miller | 250 amp |

| MIG Welding Machine | Boc | 500 amp |

| MIG Welding Machine | Lincoln Electric | 550 amp |

| Bridge crane | L=18000 mm, A: 8000 mm, Max Weight 10 Tons. |

Industrias Tanuzi S.A.

- Calle 22 No. 13 42, Bucaramanga, Colombia

- +57 7 671 1340

- gerencia@industriastanuzi.com

- www.industriastanuzi.com