Categories

- Mechanical, Electro-mechanical, Hydraulic and Pneumatic components

TALLER RET LTDA., is a company with over 40 years of experience in the manufacture, maintenance and repair of hydraulic machinery for the general industry. The Company’s commitment is to provide comprehensive services that meet customers’ needs in terms of quality and cost.

MISSION

TALLER RET LTDA., has as a mission to contribute to the development of the industry at a national and international level, through the design, manufacture, maintenance and repair of machinery, with respect towards the environment.

TALLER RET LTDA., is always seeking customer satisfaction, through the development of a long lasting relationship with customers and the delivery of efficient and timely solutions with the support of qualified personnel with extensive experience in the sector.

VISION

By the next 5 years, the Company aims to consolidate its presence in the region and be recognized as a provider of excellent quality machinery, hydraulic parts and maintenance services.

QUALITY POLICY

TALLER RET LTDA., is a company dedicated to the manufacture, maintenance and repair of machinery and hydraulic systems, with commitment towards its customers, as well as the provision of comprehensive high quality services that meet their needs through the continuous improvement of processes that generate return on investments.

Contact info #1

Contact info #2

Equipment Rental

TALLER RET offers rental services of lift tables, as well as balers for the compaction of all kinds of paper or carton. In addition, the Company has a special machine for metal compaction.

Hydraulic Systems Maintenance

TALLER RET performs preventive and corrective maintenance services, including identification of faults on power units, hydraulic pumps, cylinders, engines and control valves.

Maintenance & Repair of Hydraulic Machinery

TALLER RET offers maintenance and repair services on the following machinery:

• Electro - hydraulic platforms and lift tables.

• Hydraulic presses.

• Hydraulic cranes.

• Compactors and/or balers.

• Garbage collectors.

• Hydraulic cylinders.

• Ramps.

• Everything related to the repair of hydraulic machinery.

Balers

TALLER RET LTDA., manufactures the following balers:

Horizontal Balers:

Characteristics:

- Ideal for the compaction of any kind of paper or carton.

- Compact hydraulic system with cartridge valves.

- The feeding is performed through a cyclone duct or a conveyor belt.

- Every operation is controlled by a programmable automaton, by means of a control panel.

- The length of the compacted bale can be programmed according to the needs of the user.

- Maintenance costs are low and the hydraulic and electric spare parts are easily found in the market.

Structure:

- Balers are made of structural profiles and high quality imported sheets, reinforced where needed.

- The feeding is performed through an automatic conveyor belt or a cyclone duct.

- The baler is equipped with a pneumatic system, as an additional mechanism, for the introduction of a rubber splitter for the bales.

Hydraulic System: The hydraulic system consists of a pumping system made of a double high and low pressure hydraulic pump, a 220 VAC engine and an oil tank with a level and temperature controller.

Cylinders: Double acting cylinders with brakes made of perforated steel that are tested to exceed the normal operating pressure. The piston has an excellent design that minimizes friction. The rods are chrome plated and grinded.

Control System: The baler is equipped with a control system that performs all functions electronically for higher precision.

Vertical baler:

Characteristics:

- Hydraulic movement, easy operation, manual or electric control center.

- Double acting hydraulic cylinders with security valve.

- Special closure system in the compaction section to guarantee uniform resistance.

- High density bales thanks to the applied pressure.

- Ideal for any type of paper or carton.

- Redesign of structure for the compaction of other materials.

- Easy assembly.

Structure: Manufactured with imported steel sheets and reinforced beams where needed, with one gate specially designed for easy handling, compaction container with steel guides and a cabling system that allows the operator to take out the bales effortlessly, once tied.

Electro hydraulic control system: Three phase engine from 12 HP to 220 VAC and a magnetic starter to protect from engine overloads.

Double acting hydraulic cylinder made of special steel that has been tested to exceed the normal operating pressure. The piston has an excellent design that minimizes friction. The rods are chrome plated and grinded.

Presses

Structure: Made of high quality steel; It can be welded or bolted.

Cylinder: Made of special steel and tested at a higher pressure than the normal.

Piston: Μade of special steel, such as the rod.

Work table: It has an easy to handle wincher for easy lifting (from 10 tons or more).

Double acting pump: Every press consists of a two stage pump.

-

For up to 1000 tons.

-

For compaction of waste and other materials.

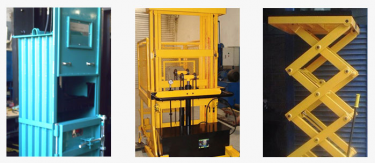

Electric-hydraulic lift tables

TALLER RET’s lift tables are the most economical option for the lifting of all kinds of products, and most importantly, do not occupy too much space as they can be mobile or stationary.

Lift tables are manufactured according to customer’s needs, with single or double scissor mechanisms for heights lower or higher than 1.5 mts respectively.

Structure: They are made of imported steel sheets and reinforced beams where needed.

Electric - hydraulic system: Three phase 220 VAC engine and magnetic starter that protects the engine against overloads.

Two hydraulic double acting cylinders made of special steel that are tested to exceed the normal operating pressure. The piston has an excellent design that minimizes friction. The rods are chrome plated and grinded. It has discharge and pressure control valves.

Hydraulic Cylinders

TALLER RET’s hydraulic cylinders are made of special steel that has been tested at a higher pressure than the actual work that will be performed and whose rods are made of resistant steel, covered by hard chrome to avoid scratches. The piston protects against friction with the casing.

Ramps

TALLER RET manufactures ramps with a reinforced U-channel structure, made of steel sheets and imported steel beams.

Hydraulic System:

The engine, pump, tank and valve make up the power unit, which also has a pressure relief system to protect the pump and guarantee the continuous operation. Siemens or Weg engines.

The single hydraulic cylinders are made of special steel and are tested to exceed the normal operating pressure. The piston has an excellent design that minimizes friction. The rods are chrome plated and grinded.

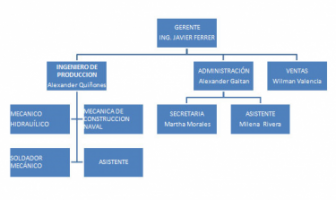

Human Recourses & Equipment

TALLER RET LTDA., has a long experience in the manufacture, assembly and maintenance of compacting and hydraulics machinery (balers, printing presses, lift tables) and throughout these 35 years has been backed by highly specialized professionals in this field.

Clients

Among TALLER RET’s most prominent clients are:

• IMOCOM,

• CARVAJAL S.A,

• INGENIERÍA AMBIENTAL,

• PRO-AMBIENTALES,

• MULTIPARTES S.A.,

• SMURFIT CARTÓN DE COLOMBIA S.A.,

• RECOLECTORA DE PAPELES,

• CONSORCIO AGROINDUSTRIAL GRAJALES,

• ALMACENES ÉXITO,

• COLPAPEL KIMBERLY,

• PAPELSA,

• INDUSTRIA DE LICORES DEL CAUCA,

• ICOBANDAS,

• EMPAQUES DEL CAUCA,

• GILLETTE DE COLOMBIA S.A.

Taller Ret Ltda.

- Calle 31a # 2 85, Cali, Colombia

- +57 2 443 8404

- +57 2 448 9542

- gerencia@tallerret.com