Categories

- Metal Processing, Parts & Components

- Services (R&D, training, engineering, consultancy, …)

PRAMEC S.A.S., is a Colombian company established in 1979 and specialised in the metalworking sector. Since the very beginning, PRAMEC S.A.S. has been recognized as one of the main contributors to the development of the automotive and motorcycle industry in Colombia. Nowadays, for its manufacturing processes the Company is equipped with computer numerical control (CNC) and conventional machinery, such as: (2) TRUMPF laser cutter machines, one (1) TRUMPF punching machine, computer numerical control lathes, folding machines and tube bending machines.

In 2008, PRAMEC S.A.S. received the Quality Management Certification ISO 9000 and in 2011, PRAMEC S.A.S. based on its solid commitment towards its customers, employees and shareholders has opened its doors to new international markets.

PRAMEC S.A.S. is highly committed towards environmental protection and is a pioneer in the implementation of safe and innovative production processes that guarantee environmental preservation.

MISSION

With more than 30 years of experience in the Colombian metalworking business, PRAMEC S.A.S. is a company that always aims for the highest quality materials in order to guarantee the delivery of high quality end products to its customers.

VISION

In the next 10 years, PRAMEC S.A.S. aims to be recognized as one of the best companies in the metalworking industry nationally and internationally.

Video Presentation:

P R A M E C'S V I D E O P R E S E N T A T I O N

Contact info #1

Spare Parts

With the support of advanced technology for the materialization of all the ideas related to metalworking, PRAMEC S.A.S. designs and manufactures stamped parts, using laser cutting, welding and CNC processes.

Machinery & Processes

PRAMEC S.A.S. is equipped with advanced machinery for the delivery of high quality end products.

Laser Cutting Machines: With the support of the latest technology available in laser cutting machinery, such as TRUMPF TRUMATIC L3030 and 2525, PRAMEC S.A.S. is able to reduce production and delivery time.

Laser Tube Cutting Machines: This brand new laser cutting tube offers new possibilities and alternatives to the design of products using conventional cutting machinery. Moreover, this laser cutting technology reduces production costs, increases efficiency and delivery time. The new TRULASER 5000, allows the Company to design parts in different thickness and geometries made of materials, such as iron, aluminium and stainless steel.

Lathes: The Company is supported with high precision Computer Numerical Control (CNC) lathes for the manufacture of metallic pieces.

Leadwell T6 series FAPUC

Machining distance = 200 mm/2"

HAAS S120 (Provided with power tools machining = 2"

Tube Bending Machines: Given the advantages of its Computer Numerical Control (CNC) tube bending machines, PRAMEC is able to manufacture precision metal pieces.

Welding Machines: Today's advances in metallurgical industry are based on the quality as well as agility of welding processes. Therefore, the Company is supported by eight (8) Metal Inert Gas (MIG) welding stations. Furthermore, the Company is also equipped with specialized Tugsten Inert Gas (TIG) machinery.

Stamping Machines: The Company is also supported by (4) conventional stamping machines of 7 to 70 tons which provide a wide variety of possibilities in the stamping of metal materials.

Machining Center: The Company is equipped with a Leadwell V40 vertical machining center with a workbench of 50cm x 1,20cm.

Electrostatic Painting Machines: PRAMEC offers the best option in electrostatic painting in compliance with environmental quality standards.

Folding Machines: PRAMEC is equipped with 2 folding machines, Durma and TruBend 7036. Its (CNC) DURMA four axes folding machine is ideal for the development of precision solutions.

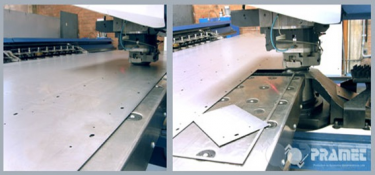

Punching Machine: The Company is equipped with a new TRUMPF 2020 punching machine for the manufacture of any kind of metallic pieces.

TRUMPF 2020 Technical Data:

• Punching operation = 2500 mm x 1250 mm

• Max. sheet thickness = 6.4 mm

• Max. punching force = 180 Kn

• Max. stroke rate = Punching (E = 1 mm) 900 1/min

• Marking = ca. 2200 1/min

• Max. number tools = with 2 clamps 19 pieces

• Tool change time (Multitool) = 0.9 s

• Space requirements = 7440 mm x 6450 mm

Videos

Laser Cutting Machine:

https://www.youtube.com/watch?v=w5asXFJcWbI

Laser Tube Cutting Machine:

https://www.youtube.com/watch?v=pqY0QbjoNyA

Lathe:

https://www.youtube.com/watch?v=aBarktyIEVc

Punching Machine:

https://www.youtube.com/watch?v=H4gu8SS53no

Tube Βending Machine:

https://www.youtube.com/watch?v=4FtT030pqHg

Welding Machine:

https://www.youtube.com/watch?v=RVKnPfRkKPM

Folding Machine:

https://www.youtube.com/watch?v=RDPeb9_mYq0

Electrostatic Painting:

https://www.youtube.com/watch?v=7ZtMFOCESmc

Punching Machine:

Clients

Among PRAMEC’s most distinguished clients are:

• BUSSCAR DE COLOMBIA

• COMPAÑÍA COLOMBIANA AUTOMOTRIZ MAZDA

• GENERAL MOTORS COLMOTORES

• GENERAL MOTORS ECUADOR

• GENERAL MOTORS VENEZOLANA

• INCOLMOTOS YAMAHA

• INFRISA

• KASSANI

• ROAD TRACK

• SERVEX

• SOLINOFF

• SUPERPOLO

• PERI

• FOSTER INGENIERÍA

• ALTRON INGENIERÍA

• DANA TRANSEJES

• DAIMLER COLOMBIA

Pramec S.A.S.

- Calle 17 Bis No. 126A 70 interior 4 y 5 Fontibon, Bogota, Colombia

- +57 1 756 4567

- ricardo.dominguez@pramec.co

- www.pramec.co