Categories

- Composites, Plastics & Rubber

Eurocarbon B.V. is a producer of braided and woven reinforcements, primarily used for composites industry. These braids and woven tapes are made out of high performance reinforcement fibers such as: glass, aramid, carbon and thermoplastics. In Sittard, the Company is consulting customers since 1982, to provide the best possible solution for their application. Through their agent network Eurocarbon can support customers worldwide.

Eurocarbon has implemented standard programs to cover a whole range of standard customer‘s applications. All programs are available on stock and ready to ship off the shelf to provide customers’ reinforcements with a minimum of lead time. When tailor made applications are required, check the “minimum requirements” section for braided and woven constructions.

Eurocarbon’s sister company Eurobraider is dedicated in series production of overbraided preforms. The production is made by Eurocarbon designed equipment and automated processes.

Eurocarbon is ISO 9001 certified.

Standard Programmes

To achieve a higher level of customer service, Eurocarbon has successfully implemented their standard product programmes for many years. All products of these programmes are in stock and can be dispatched promptly with smaller quantities if requested. Besides the standard programmes, the Company produces tailor made products according to customers’ specifications.

All products in the programmes are common articles used in the manufacturing of numerous composite components such as:

- Sports equipment

- General composite products

- Boat building

- Automotive

- Medical applications

- Aerospace applications

- Building construction

- And many more applications

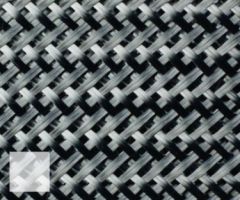

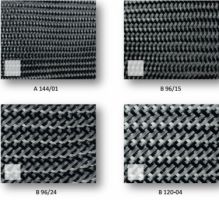

Carbon fiber braids

The tubular carbon fiber braids program is made of high quality carbon fibers. The fiber densities which we are using are 3K, 6K and 12K fibers. These fibers create respectively the light, medium and heavy braids in Eurocarbon's programme.

Aramid flat braids

Flat braids are a single layer braid (non tubular), which have the same properties of excellent drape ability. It is possible to form an “L” profile which is curved. This behavior makes it suited to reinforce radial pipe connections. For sports the Aramid flat braid is commonly used to bond 2 canoe halves together. Then the ±45° fibers will both work, compared to a fabric, which has one functional direction. Aramid fibers are very wear resistant.

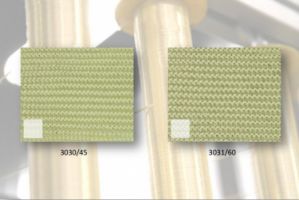

Woven tapes

Eurocarbon is a producer of both woven and unidirectional tapes in several different styles and reinforcement materials. Tapes provide reinforcement in the 0 and 90 degrees direction. With the standard program woven tapes, the Company is able to supply a selection of woven tapes, in an off-the shelf delivery. The available widths for each weave construction are marked with a “X” when available in this width. Other widths may be available.

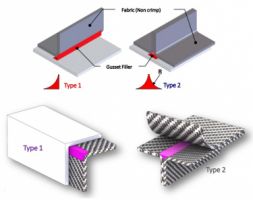

Gusset Fillers

Eurocarbon has developed a wide range of fillers. Each filler has a specific surface area in mm2 at a fiber volume fraction of 50%.

Gusset Filler Carbon UD and Glass Fiber UD

When fabrics are plied into shapes like type 1 and type 2 a hollow space is created. In injection systems this hollow space will create a runner where the resin will go through without respecting the resin front. If this behavior is not desired a filler is needed to 'plug' the created resin channel and to provide local reinforcement.

Advantages:

- Easy to form into triangular shape

- Permeability compatible with fabrics

- Constant architecture, compared to handmade fillers

- Time and money saving when it comes to blocking your undesired runners

Standard Braided Aero Filler Program

When fabrics are plied into shapes like type 1 and type 2 a hollow space is created. In injection systems this hollow space will create a runner where the resin will go through without respecting the resin front. If this behavior is not desired a filler is needed to 'plug' the created resin channel and to provide local reinforcement.

Advantages:

- Easy to form from original round shape into triangular shape

- Permeability compatible with fabrics Constant architecture, compared to handmade fillers

- Time saving compared to handmade fillers

- Made of Aero grade carbon fibers

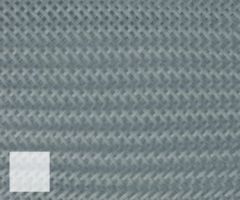

Glass Fiber Braids

The tubular glass fiber braids program is made of A-grade Eglass yarns. To cover a whole range of thicknesses, the program is made of a light, medium and heavy construction. Each range will have a specific range areal weights.

Carbon fiber elastic UD tube

The ideal solution to apply Tubular UD reinforcement around your perform. This will provide the following advantages:

- Compaction of the layers underneath, due to the elastic weft

- Once applied, the perform is stable during handling

- Time saving compared to regular UD solutions

- No adhesives used

- Easy to use

- No UD content (no high stress concentrations

Custom Made Braids and Tapes

Besides their selection of standard programmes, Eurocarbon produces a large variety of tailor made constructions. The benefit is the construction can be fine-tuned to the performance of the part and therefore save costs or increase performance compared to a standard product. To define a new braid or woven tape, there is a minimum of information required to define tailor made construction. In the next sections the required information is described.

Minimum required information for braids:

- Diameter measured at 45 degree braiding angle (or diameter at specific angle).

- Fiber materials: f.i. Carbon, E-Glass, Aramid, etc

- Hybrid construction? We can braid f.i. Carbon and Glass. Normally the ratio is 50/50 but other ratios can be selected.

- The weight of the braid at 45 degrees braiding angle / or the areal weight at 45 degrees.

Minimum required information for woven tapes:

- Width of the tape

- Weight per m2

- Fibers in warp: Fiberglass, Aramid, Carbon, etc

- Fibers in weft : Fiberglass, Aramid, Carbon, etc

- Weave style (plain/twill/satin/other)

- Threads per cm in warp (if available)

- Threads per cm in weft (if available)

Overbraiding and Turn-key Solutions

Preforms made by the Overbraiding Technique

- Overbraiding is the technique used to produce net shape cost-effective structural preforms.

- During overbraiding the braid is placed directly onto a core, which has the inner geometry of the desired preform.

- By reciprocating the core through the braiding point a pre-selected number of layers can be braided to obtain the desired wall thickness/aerial weight.

- The lightweight core can remain in the product or a lost core technique can be used for production of a hollow product.

Benefits of Overbraiding

- Cost effective method and low waste rates (5-10%).

- Reproducible due to computer control and automated processes.

- Time saving compared to building your own preforms manually.

- Braiding angles are programmable from 15° to 80°.

- 0° (UD) yarns can be integrated to form a tri-axial braid.

- The ratio between bias and UD can vary from 100/0 up to 15/85.

- Hybrids are possible in the bias and in the UD direction.

- Excellent energy absorption in crash structures. Braided structures act as crack stoppers.

- Braided structures have a good resin permeability.

- Eccentric products are possible, even banana shaped preforms.

- Preforms injected with the RTM process can have a fiber volume fraction of 55%.

What Eurocarbon offers:

- For each product an overbraiding machine and yarn configuration can be selected to produce your optimum preform.

- The Company has 15 years of experience in overbraiding and we are able, with our R&D team, to do the total preform development at Eurocarbon/Eurobraider.

- When a special braiding machine or extra equipment is needed, we can build it.

- Eurocarbon can offer a turn key solution and transfer of know-how, so you can produce your own preforms.

- Preform development and preform production can be done entirely in house.

Thermoplastics

Next to the tapes and braids for composites Eurocarbon also produces several tapes and braids of thermoplastics and natural fibres.

Among others the Company processes the following fibre materials:

- Polyester

- Polypropylene

- Polyethylene

- Cotton

- Saran

- Etc.

A selection of products that can manufactured out of the above:

- Tapes

- Straps

- Tent tapes

- Bias tapes

- Piping tapes

- Twill tapes

- Saran tapes

- Elastic tapes

- Lash tapes

- Etc.

Braided Cords

In general Eurocarbon can produce cords of a diameter between 1mm and 12mm.

- Shoelaces

- Tent Cords

- Parasol Cords

- Oil wicks

- Etc.

Elastics

- Round elastics from 1mm to 10mm

- Flat woven or braided elastics

Circular knitting-works

- Circular knitting-works for e.g. bags.

Finishing of articles

The Company can finish our products in many custom shapes.

Eurocarbon's possibilities are:

- Hot/cold products cut to length (possible chamfer cutting)

- Make up

- Blistering

- Packaging

- Tipping

- Etc.

Advanced Composites

Meeting the challenge

The plastics and composite materials market is constantly changing. Constantly expanding.

New products are generating new ideas and application areas. And new applications in turn, can stimulate the development of yet more new products.

Today, those application areas are being further expanded. Through the new levels of stiffness and strength at low weight, that advanced fibre technology brings to the production and use of composite materials.

For additional information, please refer to the attached document.

Capabilities informational files

Eurocarbon B.V.

- Dr. Nolenslaan 109, 6136 GM, Sittard, The Netherlands

- +31 46 451 72 80

- +31 46 451 61 85

- eurocarbon@eurocarbon.com

- www.eurocarbon.com