Categories

- Aircraft, Helicopter, UAV, Spacecraft & related equipment

- Metal Processing, Parts & Components

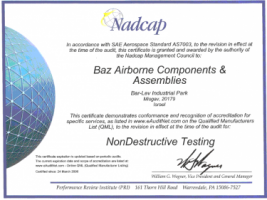

BAZ Airborne Components and Assemblies is a leading aerospace supplier in business for over than 35 year. BAZ specializes in sheet metal and extrusion fabrication, welding, surface-treatment and assembly. Current projects include build-to-print and build-to-spec using aluminum, steel, stainless steel, titanium, etc. BAZ is AS9000 certified and carries special-process/NADCAP certifications for nearly all major OEM’s.

One of the major advantages of BAZ is that almost all the required processes can be performed in-house, at the same facility. This allows BAZ to control the entire manufacturing process, both quality and lead-time, to deliver the best product to our customers.

Since 2010 BAZ works in a strategic partnership with the Aircraft Philipp Group. Due to this partnership the customers’ needs can be fulfilled from one source.

The company is ISO 9001 / AS 9100 certified, NADCAP certified for Chemical Processing; Heat Treatment; NDT and Welding.

Further, BAZ holds the following customers approvals: Boeing; Bombardier; Embraer (in progress); Elbit / Cyclone; FACC AG; Goodrich; GKN Aerospace; Gulfstream; Hamilton Sundstrand; Honeywell; Israeli Aerospace Industry (IAI); Lockheed Martin; Sikorsky; Spirit Aero; UTC Aerospace System.

Projects:

- Boeing F-15E Strike Eagle

- Lockheed F16

- Gulfstream G150/G200/G280/G650

- Cargo Conversion Boeing 737, 767 and 747

- Serial Parts Boeing 737/747/767/777/787

- Winglet retrofit Boeing 737 and 767

- Airbus A400M

- Lockheed C-130J Super-Hercules

- Honeywell AS907 Turbofan

- Bombardier Canadair Regional Jet CRJ

- Bombardier Global 7000/8000

- Embraer E190

Venturi Tube

Working with customers, BAZ developed a technology to machine Venturi tubes that allowed them to eliminate welding from the design, therefore improving the end product.

Door Handle Cover

With the disappearance of drop-hammer forming, BAZ developed a tools which can form similar shapes. The pictured interior appearance detail shows BAZ's forming and polishing capabilities.

Wing Tip

Wing-tips require accurate forming and very accurate welding. The above wing-tip is and formed at BAZ and welded using a TIG welding robot, prior to being riveted to a trailing edge machined part.

Fuel Tank

AZ designed the pictured aft-fuel tank in a build-to-specification project. It now manufactures, processes/paints, assembles and pressure tests it prior to delivering to the customer.

Technologies & Competences

- Tool design and fabrication

- Part design

- Extrusion and sheet metal forming

- NDT

- Milling

- Welding

- Heat treatment

- Surface treatment (coating, electroplating)

- Surface technologies (high gloss polish)

- Part assembly

- Customer focused services (kit)

Capabilities & Facts

- Facility area: 8.500 sqm (91.500 sqft)

- No. of parts mfg. 2013: 410.000

- No. of P/N mfg. 2013: 6.500

- No of PO`s 2013: 1.600

- No of PO lines 2013: 17.500

- Assembly hours yearly: 60.000

- Machining hours yearly: 80.000

- Sheet metal production yearly: 135.000

Main Customers

- Israel Aerospace Industries (IAI)

- GKN Aerospace

- Spirit Aerosystems

- Hamilton Sundstrand

- DenelSaab Aerostructure

- Quiet Technology Aerospace (QTA)

- Cyclone - Elbit System

- Elbit System

- Turkish Aerospace Industries inc.(TAI)

BAZ Airborne Components and Assemblies

- Mobile Post Misgav 20156, Bar Lev Industrial Park, Israel

- +972 4 956 90 00

- +972 4 955 00 91

- eytanc@bazaircraft.com

- www.bazaircraft.com