Categories

- Aircraft, Helicopter, UAV, Spacecraft & related equipment

- Maintenance Repair Overhaul and Logistics Support

- Other Aerospace, Defence and High Technology related companies

ISOTEC S.A.S., is a Colombian company created in 1995 that provides inspection and non-destructive testing (NDT) services on materials for the aviation sector and other industries.

ISOTEC S.A.S. is been approved by the UAEAC - Colombian Civil Aviation Authority - as an Aviation Repair Shop (TAR) through CDF No. 20 and is equipped with qualified personnel, as well as properly calibrated and certified equipment and resources.

ISOTEC S.A.S. has an extensive experience in the aviation, petroleum, cement and general industry, offering services such as the following:

-

Direct and remote visual inspections,

-

Dye penetrant inspection,

-

Magnetic Particle inspection,

-

Ultrasonic flaw detection and A, B & C scan ultrasound and phased Array-UT,

-

Eddy Current Inspection,

-

Current - RFT remote field,

-

Thermographic inspection,

-

Thermal diffusion flowmetry,

-

Radiographic Testing,

-

Training in all techniques according to the ANSI-ASNT CP-189 and the American Society for Non-Destructive Testing standards.

MISSION

ISOTEC S.A.S.’s mission is to provide its customers with innovative solutions by incorporating the best practices and latest technologies in the development of non-destructive inspection of aircraft components. ISOTEC S.A.S. has managed to establish a genuine relationship with its customers, ensuring its permanence and growth over time.

Contact info #1

Contact info #2

Dye Penetrant Testing

ISOTEC S.A.S. provides dye penetrant non-destructive testing services. Dye penetrants can detect workpiece surface defects such as pores and cracks, caused by thermal stresses or leaks in sealed containers. More specifically, ISOTEC S.A.S. can provide:

Visible dye inspection:

Visible dyes are used primarily in the industrial sector and more specifically for welded joints inspection. These dyes are suitable for inspecting materials at high temperatures up to 170 º C and are portable.

Fluorescent dye inspection:

Fluorescent dye inspection is used primarily in aviation industry for welded joints inspection. Although it is less portable than the visible dye inspection, it can provide a greater level of sensitivity.

High temperature dye inspection.

Magnetic Particles Testing

ISOTEC S.A.S. provides magnetic particle inspection services with a variety of applications in different industries. It is applicable only for the inspection of materials with ferromagnetic properties as it uses magnetic flow in order to detect discontinuities. Magnetic particle inspection can be performed by both stationary and portable magnetic particle equipment and can be applied on materials such as:

-

Welds,

-

Crankshafts,

-

Bolts and screws,

-

Axles,

-

Bolts and pins,

-

Blocks,

-

Casings.

Eddy Current Testing

ISOTEC S.A.S. can provide Eddy Current inspection services. Eddy Currents are electric currents that can induce magnetic fields and can detect any defects on the object under study. The stronger the applied magnetic field, or the greater the electrical conductivity of the conductor, or the faster the field changes, then the greater the currents that are developed and the greater the fields produced. Eddy currents technique is a non-destructive test method and its application does not in any way alter the properties of the object under study. This technique can be applied on:

-

Amusement park structures,

-

Boiler pipes,

-

Aircraft fuselages,

-

Aircraft wings,

-

Turbo-reactors,

-

Crankshafts, cylinders, pistons,

-

Boat hulls,

-

Heat exchangers.

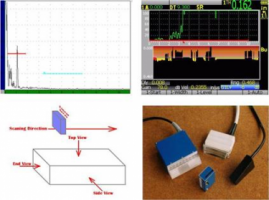

Ultrasonic Flaw Detection

ISOTEC S.A.S. can provide ultrasonic flaw detection services. Ultrasonic flaw detection is a technique based on the propagation of very short ultrasonic pulse-waves through a material, component or machine. The sound waves are launched into materials in order to detect internal flaws or discontinuities. Part of the ultrasound wave is reflected when the molecular structure changes, providing information about the location and size of the discontinuity.

Ultrasonic flaw detection can be applied on:

-

Crankshafts,

-

Bolts and screws,

-

Pipes and flow lines,

-

Tanks,

-

Axles and bolts,

-

Steel ans concrete structures,

-

Blocks and casings,

-

Exchangers,

-

Amusement park structures,

-

Boat hulls,

-

Offshore platforms.

A-scan ultrasound:

A-scan ultrasound is applicable in all types of materials with a few limitations. The beam angle allows the detection of sub-surface defects on weldings and parts with complex geometries.

Phased Array ultrasound:

Phased Array ultrasound can inspect a larger area than A-scan in a single sweep and can use up to 64 transducer elements.

C-scan ultrasound:

C-scan ultrasound is basically used for corrosion mapping, thickness loss and delamination detection.

Visual Inspection

ISOTEC S.A.S. can provide visual inspection services. Visual inspection is the most used non-destructive technique in predictive maintenance due to its versatility and low cost. ISOTEC S.A.S. has trained staff and suitable measuring equipment to perform visual inspection, using magnification, illumination and measurement instruments.

Remote Visual Inspection Technique:

This technique uses equipment that transmits images from a website without the need of human presence.

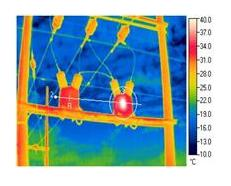

Thermographic Inspection

ISOTEC S.A.S. can provide thermographic inspection services. Thermographic inspection refers to the non-destructive testing of parts, materials or systems through the imaging of the thermal patterns at the object's surface. There are two types of thermographic inspection: passive and active. In passive thermographic inspection, the features of interest are naturally at a higher or lower temperature than the background. In active thermographic inspection, an energy source is required to produce a thermal contrast between the feature of interest and the background.

Passive Thermographic inspection is an excellent monitoring tool for the inspection of electrical equipment, power lines, bus bars, contactors, transformers, motors, electrical and thermal insulations, fireplaces, leaking seals and valves, air conditioning systems, floors and ceilings, internal combustion engines, etc.

Active Thermographic inspection is used on composite materials (glass or carbon fibers, honeycomb sandwich structures) of modern aircrafts to detect defects such as internal flaws, delaminations etc.

Radiographic Testing

ISOTEC S.A.S. can provide radiographic testing services. Radiographic testing is a non-destructive testing method of inspecting materials for hidden flaws by using the ability of short wavelength electromagnetic radiation to penetrate various materials. The radiation is partially absorbed by the object, depending on the material and its thickness. The radiation passes through the object, producing a latent image in the radiographic film. Radiographic testing can be used on aircraft structures, welder joints and in foundries.

Non-Destructive Testing Products

ISOTEC S.A.S. in addition to providing inspection services is distributing products for non-destructive testing, such as SHERWIN. More specifically, ISOTEC S.A.S. provides:

-

Dye penetrant kit,

-

Fluorescent dye penetrant kit,

-

High temperature dyes Kit (visible),

-

Magnetic particles in solution,

-

Spray presentations,

-

Materials and equipment for testing.

Customers

AEROSPACE SECTOR

• SATENA

• ISRAEL AIRCRAFT INDUSTRIES

• HELICENTRO

• FUERZA AEREA COLOMBIANA

• BRIGADA DE AVIACION EJERCITO

• AEROREPUBLICA

• AIR COLOMBIA

• SADELCA LTDA.

• SELVA LTDA.

• AVIHECO LTDA

• AEROPAZ

• SAEP LTDA

• SEARCA

INDUSTRIAL SECTOR

• ECOPETROL

• CORPORACIÓN CIMA

• TECNICONTROL

• CEMENTOS ARGOS

• EMGESA

• ISAGEN

• EMAC

• INSERCOR

• INDEEQUIPOS S.A.

• APPLUS NORTHCONTROL

• DATABANK MK

• NESTOR MORA Y ASOCIADOS

• COTECMAR

Isotec S.A.S.

- Carrera 71B No. 55 - 18, Bogota, Colombia

- +57 (1) 467 3767 / +57 (1) 467 4269

- isotec@isotec.com.co

- www.isotec.com.co