Categories

- Mechanical, Electro-mechanical, Hydraulic and Pneumatic components

- Metal Processing, Parts & Components

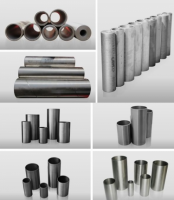

INDUSTRIAS LAVCO LTDA., is a Colombian company, located in the city of Bucaramanga, and since 1975 dedicated to the metal mechanical sector. The Company holds an ISO 9001:2008 certification and specializes in the production and marketing of cylinder sleeves for diesel and marine engines and light and heavy commercial vehicles, as well as liners for large engines, reciprocating compressors and pumps for the oil & gas industry.

The Company specializes in the manufacture of sleeves and liners according to customers’ specifications with an inner diameter of 25 millimeters to 50 centimeters and a length of up to 1.25 meters. INDUSTRIAS LAVCO is also capable of repairing large engines and reciprocating compressors.

The Company's main goal is the delivery of integrated solutions to extend the life of engines and equipment, maintaining their reliability at the same time.

In its 2,000 m2 facilities, the Company is equipped with a foundry and a machining center and is backed by 74 employees with knowledge and experience in the sector.

The Company's customer list includes not only national companies, but international companies as well, namely engine parts distributors, engine repair shops, as well as organizations of the oil and energy sectors.

Since 1992, INDUSTRIAS LAVCO LTDA. has been exporting its products to Venezuela, and since 1998 to the whole Andean community, Central America and the Caribbean. In 2003, the Company introduced its products to Mexico and the United States.

INDUSTRIAS LAVCO has established its presence in the following countries:

• USA,

• MEXICO,

• GUATEMALA,

• EL SALVADOR,

• HONDURAS,

• COSTA RICA,

• PANAMA,

• DOMINICAN REPUBLIC,

• VENEZUELA,

• ECUADOR,

• NICARAGUA.

Contact info #1

Contact info #2

Contact info #3

Contact info #4

Casting Services

INDUSTRIAS LAVCO offers casting services on aluminium, iron grey, bronze and ductile iron materials.

Machining and Assembly Services

INDUSTRIAS LAVCO specializes in the assembly and machining of industrial parts for the general industry, such as auger screws for palm oil extractors, pinions for bucket elevators, as well as thermostat housing and aluminum fuel tubes, among others.

Cylinder Repair

INDUSTRIAS LAVCO repairs gas and air compressor cylinders used in different fields, such as petroleum refineries, the petrochemical and fertilizer industries, as well as natural gas compression stations.

The Company’s activities are compliant to the API 618 Standard thus guaranteeing superior quality in the services offered. LAVCO offers NDT - Non Destructive Testing on magnetic-particles and liquid penetrants, to ensure the physical integrity of the cylinder.

Repair Stages:

-

Reception of the cylinder, initial metrological inspection,

-

Machining of the inner diameter. Visual inspection and metrology of the cylinder bore. Correction of deformations in the cylinder bore,

-

Liquid penetrant testing on the bore of the cylinder,

-

Hydrostatic test preparation,

-

Assembly of the new liner into the cylinder,

-

Honing of the inner diameter of the liner,

-

Final metrological control, report on the details of the repair, painting and finishing services and stowage of the cylinder.

Additional Services:

-

Definition of diameters,

-

Cylinder boring and grinding.

Repair of Industrial Parts

INDUSTRIAS LAVCO has also ventured into the repair of parts for the oil palm, energy, cement and oil and gas industries. For this reason, the Company’s repair range covers spreaders compressors, engine cylinder heads, shafts, bearings, connecting rods and power pivots, among others.

Industrial Solutions Development

INDUSTRIAS LAVCO has a design department that specializes in the development of solutions for the metallurgical industry. The Company has successfully re-designed compressor valves of the brand INGERSOLL RAND for the gas industry.

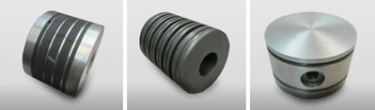

Casings

INDUSTRIAS LAVCO designs and develops casings for the automotive sector, ideal for gasoline and diesel engines, as well as centrifuged bushings and rods for seat valves.

Equipment & Instrumentation

Foundry Equipment:

- 3 Cupola furnaces, 1 tilting furnace,

- Centrifugal machinery for the automotive and industrial sector.

- 23 Lathes:

• Distance between centers: 1100-3000 mms

• Swing over cross slide: 200-900 mms

- CNC Machinery:

• Maximum work diameter: 450 mms

• Swing over bed: 651 mms

• Distance between centers: 764 mms

- Milling Machines:

• One universal milling machine

• One horizontal milling machine

• One vertical milling machine

- Boring Milling Machines:

• Diameters between 150-900 mms

• Three are horizontal and one is vertical

- Honing Machines:

• Minimum diameter: 1.5”

• Maximum diameter: 26”

- Drilling machines for maintenance tasks and automotive parts production,

• Minimum diameter: 2”

• Maximum diameter: 7”

- Measurement instrumentation,

- Phosphate machinery.

Clients

Among INDUSTRIAS LAVCO’s most prominent clients are:

• MelliNG (Automotive Line)

• DRESSER RAND (Industrial Line)

• ECOPETROL (Industrial and Service Line)

• TGI (Industrial and Service Line)

Industrias Lavco Ltda.

- Km. 4 Autopista Floridablanca Piedecuesta, Bucaramanga, Colombia

- +57 7 639 5139

- info@lavco.com.co

- www.lavco.com.co