Categories

- Aircraft, Helicopter, UAV, Spacecraft & related equipment

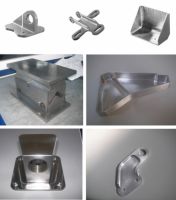

- Metal Processing, Parts & Components

Gage Aviation started its activities in 2010 and is engaged in the manufacturing of critical components for aircraft such as the Boeing 787 and the Bombardier C series. The company has also taken place in HURKUS project which is the first domestic training plane of Turkey and realized detailed manufacture of many outfits. Gage Aviation is ISO 9001:2008 and; AS 9100 certified.

CAPABILITIES

Supply Chain Management - Capability of supplying materials at home and abroad; Stock management by means of ERP system; Contracting capability and efficient follow-up system (Painting, coating, thermal processing, Arcor, blackening, welding, catopheresis normalization, anodic oxidation, etc.); Raw material follow-up system; Control of electronic consumables.

Engineering - Solid model (3D CAD Modeling); Preparation of work plans; Design of connecting apparatus; CAM (Computer Aided Manufacturing) programming; FAI (First Article Inspection); 3D Geometrical Tolerancing; MBD - Model Based manufacturing.

Software Supporting Engineering Applications - CATIA V5; Hypermill; SolidWorks; SolidCAM; Think Design; DNC Data Transfer.

Quality Control Equipments - Coordinate Measuring Machine (CMM); Profile Projection; Surface Roughness Measuring Device; Coating Thickness Measuring Device; Plasti-Form; Johnson Gauges.

Gage Aviation

- Sanayi Caddesi No:75 35180 Armutlu / Kemalpasa , Izmir, Turkey

- +902328868040

- +902328868212

- info@gage.com.tr

- www.gage.com.tr/en