Categories

- Metal Processing, Parts & Components

Activities Range:

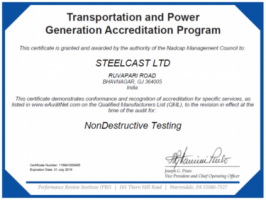

Manufacturing Steel & Alloy Steel Castings by No Bake Sand Casting Process and Shell Moulding Process. All manufacturing and testing facilities inhouse along with full fledged CNC Machine Shop and Induction Hardening facility. Inhouse NDT Facilities like UT, MPI & RT facility with Cobalt 60 & Iridium 192 sources. Inhouse Magma for pouring stimulation.

Special Strengths:

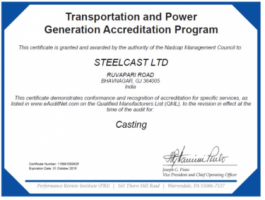

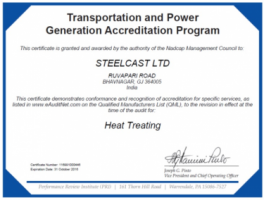

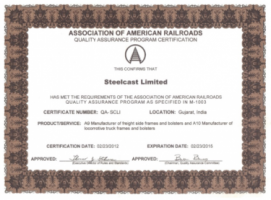

Steelcast’s special strength is in being able to successfully meet the challenges of an environment demanding continuously higher quality products. The company has been recognized as leaders in their principal product line of high integrity castings. Being an ISO 9001:2008, ISO 14001:2004 and OHSAS 18001:2007, Association of American Railroads (AAR), Lloyd’s, Class A Foundry certified company, Steelcast has norms and systems for quality assurance covering all stages, including a methodology for complete documentation, auditing and continuous self-correction.

Industries Catered to:

• Earthmoving Equipment Manufacturers

• Mining Equipment manufacturers

• Construction Equipment manufacturers

• Castings for Steel Plants

• Castings for Cement Plants

• Railways

Brief History:

1960: Established as a Partnership Firm.

1972: Converted into a Private Limited Company.

1977: Recognition of our "Research & Development Laboratory" by the Department of Science & Technology, Government of India.

1988: Converted into a Deemed Public Limited Company.

1993: Setting up of Shell Moulding Facility (Plant-2).

1994: Public issue with equity participation from M/s. Kurimoto Ltd., Japan.

1995: Certified under ISO:9002 by RWTUV, Germany (presently:TUV NORD).

1999: Certified under ISO:9001 by TUV NORD, Germany (formerly:RWTUV)

2001: Large scale development of high integrity structural castings.

2004: Accorded the status of One-Star Export House.

2006: Certified under ISO:14001 & OHSAS:18001 by TUV NORD, Germany.

2006: Commissioning of In-House CNC Machine Shop & Expansion of Shell Moulding facility.

2007: Commissioning of State-of-the-Art Induction Hardening facility.

2007: Setting up of Plant-3 (Sand Castings).

2008: Setting up of pilot No-Bake Line.

2011: Commissioning & Productionising State of Art Automated No-Bake Flaskless Moulding Line.

2011: Class A Foundry Certification accorded by Indian Railways (RDSO)

2012: Accreditation by Association of American Rail Road (AAR) for “Quality Assurance Certification as per M1003” facilitating manufacturing of Side Frame & Bolsters for American Railroad Freight & Locomotive Industry.

Steelcast Limited

- Ruvapari Road, Gujarat, 364 005, Bhavnagar, India

- +91 278 251 9062

- +91 278 251 9831

- info@steelcast.net

- www.steelcast.net