Regulators Validate Smith Foundry Testing

Regulators from the Environmental Protection Agency (EPA) and the Minnesota Pollution Control Agency (MPCA) have verified the results of independent stack testing at Smith Foundry and confirmed that Smith Foundry’s air emissions are in compliance with its Minnesota air permit and applicable limits.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20240212923502/en/

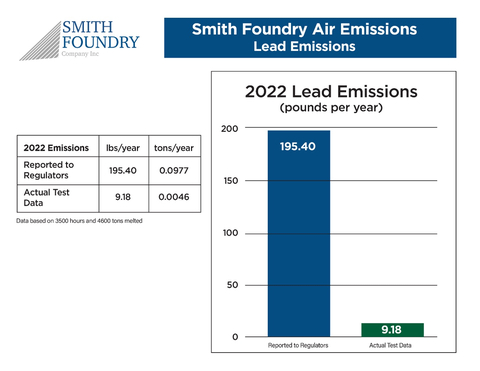

Reported testing Dec. 2022 comparison to actual testing Dec. 2023 (Graphic: Business Wire)

From the Minnesota Pollution Control Agency:

“The test results, which MPCA shared in late January, verify that Smith Foundry is not emitting more particulate matter than allowed by its permit. The tests also detected low levels of lead coming from the facility.”

The results confirm that Smith Foundry’s air emissions are in compliance with the air permit issued by the MPCA and applicable emissions limits. Further, the various tests show that Smith Foundry has some of the lowest lead emissions for manufacturing companies in Hennepin County and, according to Stantec, this level of emissions does not cause any adverse health impact for people living in the neighborhood.

The testing was ordered by the EPA and the results were submitted to the EPA and MPCA on Jan. 24. The testing was conducted by Alliance Technical Group on Dec. 12-14, 2023, and was observed and monitored by MPCA and EPA officials. Community members were invited to observe the testing.

A copy of the letter from MPCA to Smith Foundry is here: https://www.pca.state.mn.us/sites/default/files/NOPTV-SmithFoundry-Dec23.pdf

Extremely Low Lead Levels

Smith Foundry also engaged Stantec, a leading global engineering firm that provides environmental, health and safety services and is regularly engaged by EPA, MPCA and other regulatory agencies, to analyze the test results with respect to lead emissions.

In a report provided to the company, Stantec stated that the “stack test from December 2023 at the five baghouse emission points from Smith Foundry produced extremely low lead emission results” and “[i]n Stantec’s opinion, based on a risk and hazard evaluation of the stack test results and Smith Foundry’s facility, emissions of lead at the reported levels would not cause any adverse human health effects for people living in the vicinity of Smith Foundry’s facility. This would be true even if they lived at the property line.”

The independent “stack testing” conducted at each of Smith Foundry’s five dust collector emission control units measured particulate matter control efficiencies exceeding 99.5%. Under Smith Foundry’s MPCA-issued air permit and MN Rule 7011.0070, the fabric filter dust collectors must control collected particulate matter emissions to at least 99%.

In addition, the visible emissions at each of the dust collector exhausts measured a 0% opacity reading. Under Minn. Rule 7011.0105, existing and new units are permitted to operate up to 20% opacity.

Smith Foundry Statement

“The test results, in addition to the surprise MPCA inspection we passed in November, confirm that Smith Foundry is meeting the state and federal standards for air quality,” said Adolfo Quiroga, president of Smith Foundry. “I want people to know that we are committed to ensuring clean air and providing people in Minneapolis, including the East Philips neighborhood, with well-paying, good union jobs. I believe that the test results and the repairs, improvements, and investments we’ve made since purchasing Smith Foundry 13 months ago demonstrate that commitment. We look forward to continuing to work with state and federal regulators and engage with the community as we continue to complete our application for a new air permit.”

In addition to stack testing, Smith Foundry contracted an independent laboratory to determine the lead content of raw materials used in the manufacturing process and samples of finished product. The metal analysis of three different samples demonstrated the lead content is less than 0.001% using the most precise certified lab analysis method. The raw material analysis was conducted by Element Materials Technology (an A2LA registered laboratory) on Nov. 20, 2023.

Based on the collected data from the stack testing and the metals analysis, lead emissions from Smith Foundry are less than 0.7% of the “major source permitting thresholds.” In Minnesota, the major source permitting threshold for lead is 0.5 tons/year. (See Facts About Processes and Equipment That May Require Air Permits from MPCA.)

Additionally, the test results show that the total annual lead emissions from Smith Foundry equate to less than 0.035% of the total lead emissions reported in 2020 for the entire state of Minnesota and less than 0.35% of the total lead emissions reported in 2020 for Hennepin County. Reported lead emissions primarily originate from airports, electric generation, industrial processes, and fuel burning.

The lead emissions figures on annual emission reports from the previous ownership of Smith Foundry’s facility were overestimated. This is because the estimates relied on an emission study published by the EPA in 1970. The lead content in the metal melted during that 1970 study had significantly higher lead concentrations compared to the metals currently processed by Smith Foundry.

The next steps in the MPCA permitting process include an environmental analysis and community engagement beginning in May 2024. A new air permit could be issued by the end of the year.

Zynik Capital purchased the assets associated with Smith Foundry’s business in December 2022 and has made significant investments to improve the facility, including to reduce emissions and improve health and safety.

View source version on businesswire.com: https://www.businesswire.com/news/home/20240212923502/en/