Categories

- Metal Processing, Parts & Components

Exechon Enterprises L.L.C. is a Joint Venture between Lockheed Martin, Tecgrant AB (formerly Exechon AB), a Sweden-based technology company and Abu Dhabi-based Injaz National.

Exechon is committed to providing the most advanced Parallel Kinematic Machine technology capable of transforming manufacturing processes and adapting to integrated factory workflows.

Exechon’s patented technology is designed to provide full turnkey solutions; allowing customers to leverage an advanced manufacturing platform that meets their future needs and requirements.

VIDEOS

INTERVIEWS

Interview with Mr. Jon Badrock, CEO Exechon Enterprises LLC. (Jan 18, 2019) Source: Epicos (link)

PRESS RELEASES

Exechon Joint Venture Announces XMini Automotive Manufacturing Sale to UAE-Based REFCO Metals (Jul 17, 2018) Source: Cision PR Newswire (link)

Ascent Expands Portfolio with Faster, More Accurate Aerospace Robotics (Jun 28, 2018) Source: Cision PR Newswire (link)

Contact info #1

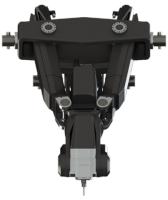

XModule

Comprised of 5-axis carbon fiber structure, spindle, Integrated MQL system and full Siemens 840D controller, the XModule can be utilized in many ways. Mounted in virtually any orientation, the possibilities are endless and allows the XMINI to provide machine tool capabilities with robotic flexibility integrated into many custom manufacturing solutions.

With its modular design, the XMINI can be disassembled, relocated, reassembled and recalibrated in existing production.

To achieve the specifications of the XMINI, it was essential to reduce both the size and weight of the unit by scaling the previously proven XT design down in size as well as replacing previous heavy components with new lighter components.

Major structural components like the actuators, gimbals and housings have been redesigned out of the latest in carbon fiber technology, drastically reducing weight, while providing the stiffness required. Aluminum has been used in lieu of steel and/or cast iron for some of the other parts.

The XMINI module has the size of a cube 1200 mm x 1200 mm x 1200 mm (4' x 4' x 4'), a total weight of 250kg/550 lbs, and can easily be disassembled into four major components for relocation inside e.g. a wing box.

XMobile

With the XMINI mounted on a mobile platform, the module can simply be relocated using a standard pallet mover or forklift, to different areas in a factory and adapt its machine coordinates to part coordinates.

Acting as a mobile machine tool, the XMobile replaces manual operations, special machines or big machine tools, and allows for one XMobile to operate on different parts and at different locations throughout a factory.

XTurnSlide

The 5-axis XMINI combined with a turntable mounted on a slide unit, increases the work envelope drastically and provides a 6-sides in one setup machining of up to 2000 mm (78 inch) long components.

Powered by XAutoCMM, that measure the shape of the parts pre-machining and compensate for part inconsistency as well as fixture deformation, the XTurnSlide reduce the scrap rate, eliminate deburring, reduce the cost of fixtures and substantially improve part quality.

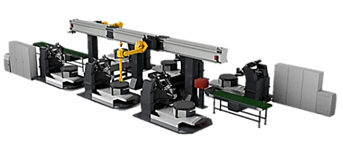

XRail

The XMINI mounted on an additional X-Axis, expands the work envelope dramatically, allowing machining of 1 part up to 14 meters in length or 2 parts 7 meter long.

The XRail can also be equipped with single or double trunnion, allowing for machining of parts up to 2000 mm (78 inches) diameter and 14 meter long.

XDemo

The XMINI mounted on a rigid steel base, combined with a t-slot machine table, provides the flexibility for mounting components with inexpensive workholding. Optional stand components allow for the XMINI to be rotated 180 degrees, enabling larger parts to be presented to the work envelope, with the XMINI positioned horizontally.

Aerospace

APPLICATION

Large Parts Trimming & Drilling

CHALLENGE

Move a machine over large areas and adapt machine coordinates to part coordinates in multiple zones on a part

VALUES

Quality

XMINI's capability to adapt to surfaces and drill perpendicular to the same gives an desirable quality compared to manual drilling

Human

Manual drilling wears out people very fast, and is a big problem in the aerospace industry

Energy

The XMINI consumes less than 50% of the energy compared to equivalent systems

Economical

The price-performance of the XMobile is a fraction of an equivalent automated system with more flexibility and mobility

Automotive

APPLICATION

Chassis & Frame Parts Machining

CHALLENGE

Adapt part programs to inconsistent part shapes and perform burr free machining on six sides with Cpk 1.67

VALUES

Quality

XMINI in combination with XAutoCMM is a revolutionary process to achieve the quality of formed, stamped and casted aluminum

Human

Manual deburring wears out people and can be avoided with the XMINI's high dynamic capabilities

Energy

The XMINI consumes less than 50% of the energy compared to equivalent systems

Economical

XMINI combined with XAutoCMM reduce the scrap rate, eliminate deburring, reduce the cost of fixtures and substantially improve part quality

Fabrication

APPLICATION

Architectural Profiles & 3D Decoration

CHALLENGE

Machine 3D decorations and apply other features such as screws on flat and curved profiles for e.g. window & door and hand rails

VALUES

Energy

The XMINI consumes less than 50% of the energy compared to equivalent systems

Economical

There is a market desire for decoration on buildings and the XMINIs 5-axis capability on long parts will add value to the products and allow for automation in a traditional manual industry

Integration

APPLICATION

Miscellaneous machining

CHALLENGE

Applications where standard Exechon products don’t apply but require special designed systems

VALUES

Quality

Ref. Aerospace & Automotive

Human

Ref. Aerospace & Automotive

Energy

The XMINI consumes less than 50% of the energy compared to equivalent systems

Economical

The ability to utilize one and the same module for various applications in a complex integrated system means less investment and higher uptime

In Situ

APPLICATION

In-Field Repair Machining

CHALLENGE

Take a machine apart, ship it to e.g. an onshore or offshore platform and put it back in operation for repair work on site

VALUES

Economical

XMINI on e.g. platforms shorten “down time” during maintenance and repair, and the industry avoids costly shipping of parts long distances on land or sea

Drilling Capabilities

Aluminium Drilling: Hole diameter 11 mm

Titanium Drilling: Hole diameter 30 mm

Carbon Fiber Reinforced Polymer (CFRP) Drilling: Hole diameter 11 mm

Stack: Titanium, Carbon Fiber, Aluminium Drilling: Hole diameter 11 mm

Ascent Aerospace

Ascent Expands Portfolio with Faster, More Accurate Aerospace Robotics

Ascent Aerospace, a leading provider of aircraft assembly line integration services, has added Exechon Enterprises LLC’s parallel kinematic robots to their portfolio of manufacturing automation solutions. Exechon’s Parallel Kinematic Machine (PKM) technology offers the stiffness of a machine tool with the dynamic 5-axis capability of an articulated-arm robot, for faster, more accurate assembly and higher overall equipment effectiveness.

Exechon’s latest innovation, the XMini, is accurate to 30μ, a step-change improvement over existing aerospace robotic solutions, which are limited in stiffness and speed. XMini’s rigid PKM technology maintains accuracy to 3G acceleration, for faster cycle times. Unlike traditional machine tool monuments, the light, carbon fiber XMini can be mounted in any orientation, even upside down, for full 5-axis capability. The modular XMini can be taken apart and reassembled inside spaces traditionally inaccessible to machines or people, such as an aircraft wing box.

Ascent Aerospace has entered into a licensing agreement with Exechon Enterprises LLC, a joint-venture company comprising Abu Dhabi-based Injaz National, U.S. global security and aerospace company Lockheed Martin [NYSE: LMT], and Sweden-based Tecgrant AB. The agreement authorizes Ascent to integrate Exechon’s parallel kinematic robots into their automated manufacturing cells.

Link to Press Release (June 28, 2018)

REFCO Metals

Exechon Joint Venture Announces XMini Automotive Manufacturing Sale to UAE-Based REFCO Metals

Exechon Enterprises L.L.C., a joint venture (JV) company comprising of U.S.-based global security and aerospace company Lockheed Martin (NYSE: LMT), United Arab Emirates (UAE) -based Injaz National and Sweden-based Tecgrant AB, has sold an XMini industrial robotic manufacturing tool to REFCO Metals L.L.C., a UAE-based manufacturer of aluminum assemblies for luxury automobiles.

Link to News Release (Jul 17, 2018)

Exechon Enterprises L.L.C.

- ICAD 1, Warehouse 7/Unit 2, Abu Dhabi Business Hub, Mussafah, 778094, Abu Dhabi, United Arab Emirates

- +971 2 448 6126

- xmini@exechon.com

- www.exechon.com